Troubleshoot the main points of failure of the high and low temperature cooling system

When the industrial high and low temperature cooling system is in use, what is the general reason if the temperature cannot drop down? How should we deal with such failures?

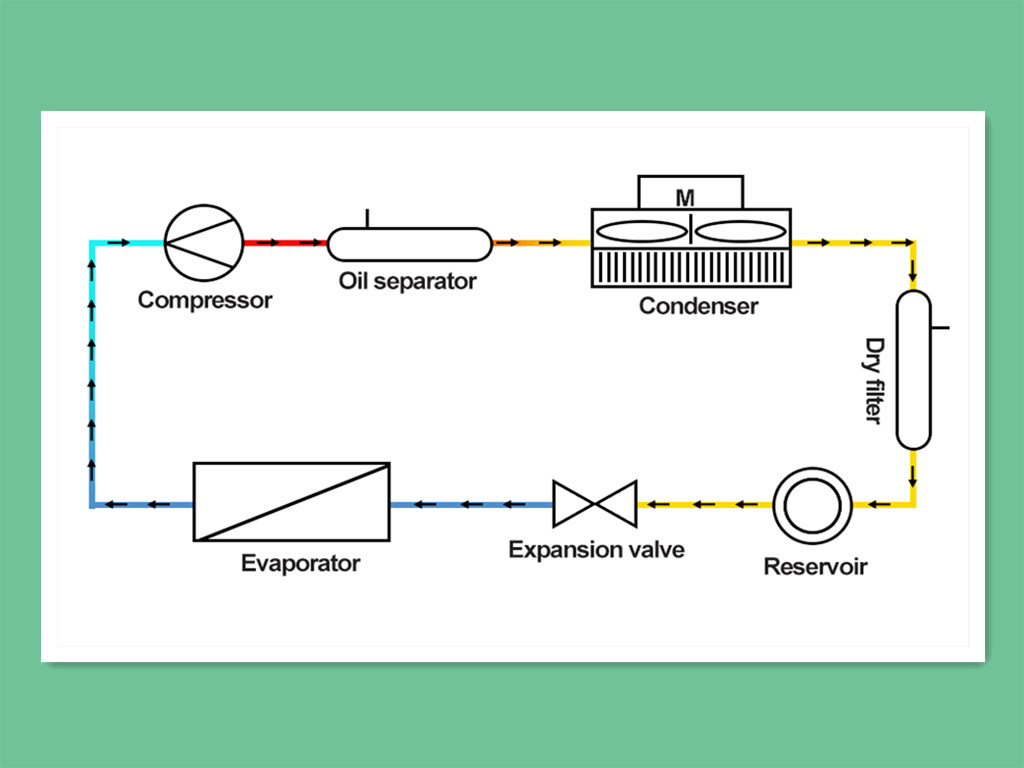

Let’s first analyze the principles and methods of industrial cooling. The circulating heat transfer medium is different. Generally, the high and low temperature cooling system industry mostly uses direct cooling, while indirect cooling is used, with plate heat exchangers or oil coolers installed inside. In other devices, the heat medium and cooling water source in the system exchange heat in the heat exchanger to reduce the temperature of the medium.

The temperature of the high and low temperature cooling system cannot be reduced. Generally, we conduct inspection and maintenance from the following aspects:

1. The cooling solenoid valve is damaged: it is necessary to check whether the solenoid valve coil can work normally, if it is damaged, it needs to be replaced; the panel does not output a cooling signal, carefully check the circuit or use the component replacement method to check.

2. Circuit failure: Check the circuit part of the system, the cooling water inlet or outlet pipeline is blocked: check whether the valve in the cooling water pipeline is fully opened, and ensure that the flow and pressure of the cooling water are sufficient, and the heating contactor is stuck, Always heating: observe the pull-in state of the contactor, and worsen damaged electrical parts.

In addition to troubleshooting the above two possible causes of failure, we also need to check whether the cooling plate is replaced or the cooling exchanger is blocked.

The advantage of using indirect cooling is that it has high temperature control accuracy and strong adaptability. It can be applied to the temperature control of high and low temperature cooling system industries. And because the heat transfer medium is cooled first, the cooling impact on the temperature control equipment is relatively small. Of course The disadvantage is that the cooling speed is relatively slow, and the price is more expensive than direct cooling.

Related recommendations

-

Characteristics of Industrial Constant Temperature Recirculating Chiller

2237Points for attention in the use ofindustrial constant temperature recirculating chillerIndustrial constant temperature recirculatingchillers are widely used in pharmaceutical, chemical and laboratory. Next,let's introduce the characteristics...

View details -

What are the reasons for the power consumption of large-size refrigeration units?

1566During the operation of large-size refrigeration units, the cooling capacity and working conditions are the main issues of power consumption, but in order to avoid some unnecessary power consumption, we need to understand clearly. When the scale o...

View details -

What Should Be Noticed In Detail When Installing A Precision Chiller?

1921First, when installation, everyone needs to check whether your cold water machine works normal, whether the accessories are all right, whether there is damage, so as to avoid problems in installation. Second, when installing, the site of the preci...

View details -

Why does the glass reactor need a heating refrigeration circulator in use?

1463The glass vacuum reactor is of double-layer glass design. The inner layer is filled with reaction solvent for stirring reaction, and the interlayer can be connected with different cold and heat sources (freezing liquid, hot water or hot oil) for c...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier