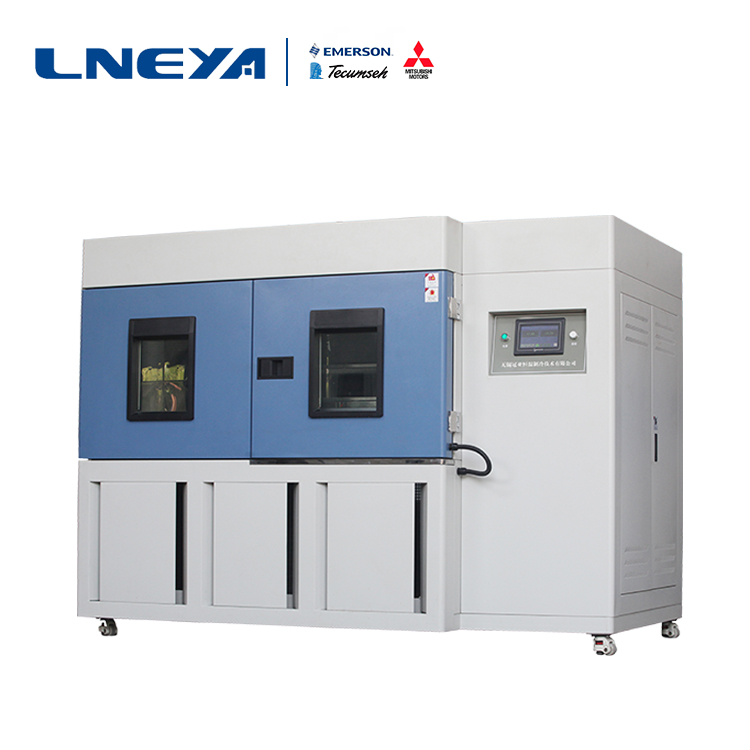

Small hot and cold shock test box use note

Small thermal shock test chamber is non-explosion-proof product (explosion-proof needs to be customized), please do not use it in the environment with flammable or explosive gas. In order to avoid small thermal shock, the test box is faulty, please provide rated voltage. Power supply within range. To prevent electric shock or malfunction and malfunction, do not turn on the power before installation and wiring are completed. Please try not to open the test box door during work. If it is opened at high temperature, it may cause burns to the operator. Opening at low temperature may cause frostbite to the staff and may cause the evaporator to freeze and affect the cooling effect. If it must be opened, please do a certain amount of protection work, prohibit unauthorized disassembly, processing, modification or repair of small thermal shock test box, otherwise there will be abnormal action, electric shock or fire.

The danger of disaster.

The vents of the small thermal shock test chamber should be kept open to avoid malfunction, abnormal operation, reduced life and fire. If the machine is damaged or deformed when unpacking, please do not use it. Be careful not to let dust, wire ends, iron filings or other things enter during machine installation, otherwise malfunction or malfunction will occur. Wiring must be correct and must be grounded. Failure to ground may result in electric shock, malfunction or malfunction, abnormal display or large measurement error.

The small thermal shock test box needs to check the terminal screws and the fixing frame regularly. Please do not use it in loose condition. During operation, the power input terminal cover must be installed on the terminal block to prevent electric shock. When the instrument is in operation, the safety should be fully considered before the operation of modifying the settings, signal output, starting, stopping, etc., and the wrong operation may cause damage or malfunction of the working equipment. Please wipe the meter with a dry cloth. Do not use alcohol, gasoline or other organic solvents. Do not splash water on the meter. If the meter is immersed in water, stop using it immediately, otherwise there is danger of electric leakage, electric shock or fire. Internal parts have a certain life span. For continuous and safe use of the instrument, please perform regular maintenance and maintenance. When disposing of this product, please dispose of it according to industrial waste.

We should pay attention to the use of attention points, so as to avoid the failure of the small thermal shock test chamber during use and improve the efficiency in operation.

Related recommendations

-

Chiller for heat deflection temperature instrument

930Temperature range: The temperature of the cooling water is usually required to be between 6 ℃ and 18 ℃.Temperature difference requirement: The temperature difference of the cooling water should be controlled wit...

View details -

LED LCD display thermal test system operation process

945The integrated semiconductor industry has developed rapidly in the past two years, which has driven other industries around it. The chip thermal test system is one of the products. In order to avoid machine failures in the LED liquid crystal displ...

View details -

What are the precautions when choosing an industrial chiller?

812An industrial chiller is a refrigeration device that assembles a refrigerator, condenser, evaporator, expansion valve, control system, and switch box on a common base or frame. According to the heat removal method of the unit, it can be divided in...

View details -

Precautions for installation of special chiller for new energy testing

956The installation of the special chiller for new energy testing is an important link before operation. The quality of the installation is directly related to the operation and operation status of the special chiller for new energy testing. So, what...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier