What is the refrigerant of the recirculating chiller

Different industries have different

requirements for the refrigeration temperature of the recirculation chiller, so

the selected refrigerant is also different. When choosing a recirculation

chiller, it is also necessary to have a clear understanding of the refrigerant.

Choose the corresponding refrigerant

according to different equipment models:

All users who are engaged in the

refrigeration industry must have a clear understanding of refrigerants. The

types of refrigerants used in different temperature ranges are different.

Generally speaking, the main types of refrigerants are: R12, R134, R600,

R152/R22, R410A, R404, R23, etc. In the past, many manufacturers used Freon as

a refrigerant, but today with the continuous development of environmental protection,

the LNYEA circulating water cooling equipment has abandoned this

environmentally friendly refrigerant and used environmentally friendly

refrigerants such as R404, R23, and LNEYA mixed refrigerants. Choose the

corresponding refrigerant for different equipment models.

When selecting a refrigerant, a

comprehensive technical analysis should be carried out according to the

specific situation:

Refrigerant is also called refrigerating

medium, commonly known as refrigerant in some areas in the south. It is a

working substance that continuously circulates in the refrigeration system and

realizes refrigeration through its own state changes. The refrigerant absorbs

the heat of the cooling medium (water or air, etc.) in the evaporator and

vaporizes, and transfers the heat to the surrounding air or water in the

condenser to condense. The selection of refrigerant is a more complicated

technical and economic issue, and there are many factors that need to be

considered. When selecting, a comprehensive technical analysis should be

carried out according to the specific situation.

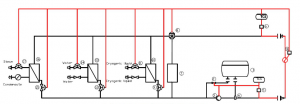

Environmentally friendly refrigerants for

recirculation chillers are different from Freon refrigerants. The big advantage

is that it has zero potential for damaging the ozone layer and can meet

environmental protection requirements. At the moment when the theme of

environmental protection is developing, it is very much in line with the

development theme of the great era. On the other hand, refrigerants have small

molecules, light molecular weights, strong permeability, and are very easy to

absorb water and are not compatible with mineral oil. Therefore, the amount of

refrigerant has higher requirements for the cleanliness of circulating water

refrigeration equipment. Therefore, LNEYA adopts fully enclosed circulation

pipelines to reduce the occurrence of refrigerant leakage, improve the

operating efficiency of the recirculation chiller, and reduce enterprise costs.

There is still an important maintenance

problem in the use and promotion of recirculating chiller refrigerants. Due to

the lag in the market, not only the dedicated refrigerants, refrigerating oil,

lubricating oil, filter drier and compressor parts are less and expensive, but

also the maintenance equipment and process requirements are also very high. The

fully enclosed circulation pipeline used by LNEYA, The accessories are all

brand, with better quality and lower failure rate.

If you purchase LNEYA related equipment,

you can contact your sales engineer for after-sales consultation about the

addition and use of refrigerants, our contact email sales@lneya.com

Related recommendations

-

-

Chemical synthesis process control system temperature control system TCU

1710Today, let's talk about our DCS integrated control system (temperature and other control of synthetic process). Scalability: the system is an open system, which provides standard TCP / P data communication interface protocol, interface software an...

View details -

-

The Application of Industrial Chillers

1386The chiller machine is needed in a lot of industries, basically chemical, medical, pharmaceutical industries are involved, then what industry can Wuxi Lneya chiller meet in the end? It is known that we are one of the top chiller manufacturers. Th...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier

![Meet on December 16-18 [CPHI] Shanghai New Inte... Meet on December 16-18 [CPHI] Shanghai New Inte...](https://www.lneya.com/wp-content/uploads/2023/05/3-3-1-300x150.jpg)