High and low temperature humidity test chamber performance

Applicable to aerospace products, information electronic instruments and meters, materials, electrician, electronic products, all kinds of electronic vitality in high and low temperature or hot and humid environment, test its performance indicators

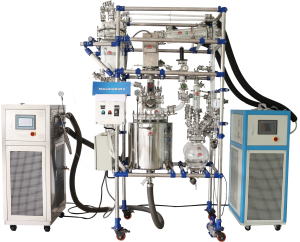

Performance characteristics:

1. It has wide temperature control range, which can meet the needs of users.

2. With a unique balanced temperature control method, with stable and balanced heating capacity, high precision and high stable temperature control can be carried out;The temperature is displayed by touch screen, easy to read, precise and convenient.

3. The temperature error can be adjusted to meet your more accurate test conditions.

4. It has the function of automatically selecting the running refrigeration circuit with the setting of temperature, and the operation is simple.

5. The box door is equipped with a large observation window, which can observe the test status of the test sample at any time.

6. with functions of high temperature on, can be in when the temperature in the oven to 100 ℃, can open the refrigerator, facilitate continuous round-trip experiment was carried out between the high temperature and low temperature.

7. It has the functions of self-diagnosis, overload protection of refrigerator, high pressure switch, overload relay, thermal protection device, etc., to ensure the safety of use.

8. Use a multi-wing fan to circulate the wind in a strong way to avoid any dead Angle, so that the temperature can be evenly distributed in the test area.

9. Wind circulation is designed with wind return wind. The wind pressure and wind speed are in accordance with the test standard.

10. Temperature rise, cooling and system complete independence can improve efficiency, reduce test cost, increase life span and reduce failure rate.

11. The water tank is placed on the side of the unit, and there is water shortage and automatic protection, so as to facilitate the operator to replenish the water supply.

12. The humidification system pipeline is separated from the control circuit board, which can avoid the failure of water leakage in the humidified pipeline and improve the safety.

13. The system of waterway system is opened by door, which is convenient for maintenance and maintenance.

14. In refrigeration system, air cooling or water cooling is adopted in condensation.

Related recommendations

-

What are the components that improve the performance of industrial chillers?

1797Industrial chillers are indispensable equipment in LNEYA production. With its normal operation, we will have better work efficiency and higher product quality. The refrigeration system of an industrial chiller is mainly composed of four core compo...

View details -

Temperature control unit necessary for Chinese medicine chemical raw material extraction-TCU

1812The production process of traditional Chinese medicine raw materials is relatively complicated: long process, many pipelines, and complicated operations; and most of the preparation raw materials are unstable, such as high environmental parameters...

View details -

How to clean air control system?

1794In order to respond to the requirements of the two types of society in the country, environmental protection and conservation have become increasingly important. Therefore, in order to extend the life of the product, it is still necessary to have ...

View details -

The advantages of water cooled chiller you need to know

1699Industrialchillers can be generally divided into water-cooled and air-cooled according tothe type of refrigeration. The heat exchange medium of Water Cooled Chillers iswater.LNEYA has designed and developed a new type of temperature controlequ...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier