Refrigeration heating machine pipe description

When the refrigeration and heating integrated machine is running, the user will find out whether the fully enclosed pipeline affects the overall performance of the equipment. The LNEYA refrigeration and heating integrated machine adopts a fully closed circulation pipeline, and there is no oil mist and water vapor generation when operating at high and low temperatures. What is the importance of piping design by continuously improving the operating efficiency of the refrigeration and heating machine?

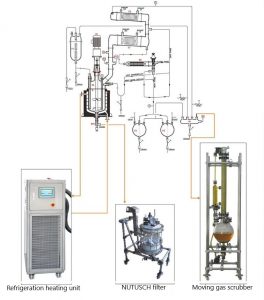

The refrigeration and heating integrated machine adopts a fully enclosed pipeline design and adopts a high-efficiency plate heat exchanger to reduce the demand for thermal fluid and improve the heat utilization rate of the system to achieve rapid rise and fall temperature. The heat-conducting medium is in a closed system with an expansion vessel. The heat-conducting medium in the expansion vessel does not participate in the circulation. Whether it is high temperature or low temperature, the temperature of the expansion tank is normal temperature to 60 degrees, which can reduce the absorption and evaporation of the heat-conducting medium during operation. risk.

After installing the compressor welding pipeline, the refrigeration and heating integrated machine should keep the whole system clean and avoid the accumulation of other impurities such as welding slag inside the refrigeration and heating integrated machine system, resulting in serious failure during compressor operation. Vibration is inevitable during operation. In order to reduce the vibration of the pipeline, it is recommended to use copper pipes as suction and exhaust pipes. This allows the copper tube in the line to reduce vibration during normal operation of the compressor. If the pipes in the system are to be steel pipes, proper welding techniques are important to avoid stresses in the piping system. These internal stresses cause resonance and noise, which will reduce the life of the compressor.

After the welding and heating machine is finished, the oxidized impurities and debris generated in the pipeline due to the welded pipe shall be removed in time. If these impurities enter the compressor, the oil filter may be blocked and the lubrication system and the capacity adjustment system may be invalidated. If the suction and exhaust flanges of the compressor are made of cast steel, they can be directly welded to the pipe. After welding, it should be cooled in the atmosphere, and water should not be cooled.

LNEYA refrigeration and heating machine and other equipment in the overall performance of the above is a certain difference, different manufacturers of equipment in the price and configuration is different, so you need to pay attention to a price of a shipment.

Related recommendations

-

Refrigeration control system compressor failure caused by oil pressure

1545If there is no oil pressure in the refrigeration control system, check the oil pump piping system connection for oil leakage or blockage. If the connection is loose, the joint should be tightened. If it is blocked, the oil pipeline should be clear...

View details -

How to avoid improper operation of heating and cooling circulator?

1580When the user runs the heating and cooling circulator, the operation needs to follow the instructions. Then, how to avoid unsuitable operation? LNEYA heating and cooling circulator has multi-function alarm system and safety function. It uses plate...

View details -

Chip high and low temperature aging test box system design

1661The high and low temperature aging test box of the chip is applied to the high and low temperature test industry of the chip. The design schemes provided by the high and low temperature aging test box manufacturers of different chips are different...

View details -

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier