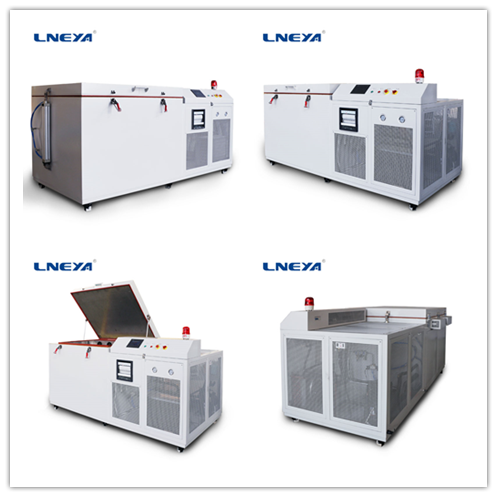

Description of LNEYA industrial ultra-low temperature freezer

LNEYA industrial ultra-low temperature freezer is mainly used in industrial cold treatment to precipitate uniform, fine and dispersed carbides on the metal structure matrix. The appearance of such a carbide will bring about a significant increase in the wear resistance and friction properties of the metal, and the hardness will also increase, and will directly increase the life of the wear member. The ideal product to replace liquid nitrogen.

It can also be used for cold shrinkage of copper sleeves, bearings, etc., and is widely used in precision mechanical assembly. It is used in large equipment (automotive, large engineering machinery, aircraft parts, aerospace equipment parts, military equipment parts, ultra-low temperature test. It can be used for touch screen, display freeze degumming, disassembly.

Different manufacturers have different needs, so most of the cold processing equipment is made according to the requirements. Please provide the following indicators when ordering:

1 maximum load;

2 liner size: length, width, height;

3 Full load cooling to the target value time.

LNEYA industrial ultra-low temperature freezer uses nickel-chromium alloy electric heating heater, the controller itself has 2 protection, plus independent temperature limiter protection. Cooling of the equipment: (25 ° ambient temperature, under no-load conditions, from 0 degrees to -110 degrees for about 1.5 hours); (25 ° ambient temperature, under no-load conditions, from 0 degrees to -140 degrees About 2 hours); the device will have a slightly different cooling rate due to changes in ambient temperature.

The control mode of the device is ASET multi-function controller; 7-inch color touch screen, display setting temperature, measuring temperature and so on. The temperature curve records the temperature, and the U disk data is exported. The format is excel table and the fault record. The circulating air inside the cabinet: 2100m3/h; 2750m3/h; 4500m3/h….. When the door is opened, the internal circulation fan is automatically turned off, and the door opening state is displayed on the touch screen screen.

Compressors for all temperature ranges are international brands: Emerson Copeland compressors, which use single-compressor automatic cascade refrigeration technology.

Related recommendations

-

Refrigeration heating machine pipe description

1658When the refrigeration and heating integrated machine is running, the user will find out whether the fully enclosed pipeline affects the overall performance of the equipment. The LNEYA refrigeration and heating integrated machine adopts a fully cl...

View details -

Ways to make ultra-low temperature circulating chillers more energy-efficient

1211In modern times, environmental protectionand energy saving is the development theme, so is the industrial chiller. Then,how to improve your industrial chiller to be more energy conservation? First, to prevent and reduce the pipescaling of ult...

View details -

Method for connecting reaction kettle and electric control cabinet of reaction equipment

1575The supporting equipment of the reaction kettle is the temperature control product provided by our company for the majority of users for the users. When the user selects the equipment for the reaction kettle, it is necessary to understand the conn...

View details -

How to solve the problem that the cooling pump centrifugal pump power consumption becomes larger?

1622There are many opportunities for the centrifugal pump in the chiller, but the failure of the centrifugal pump will affect the use of the chiller. Therefore, do not worry if the centrifugal pump power becomes larger, find out the cause in time, and...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier