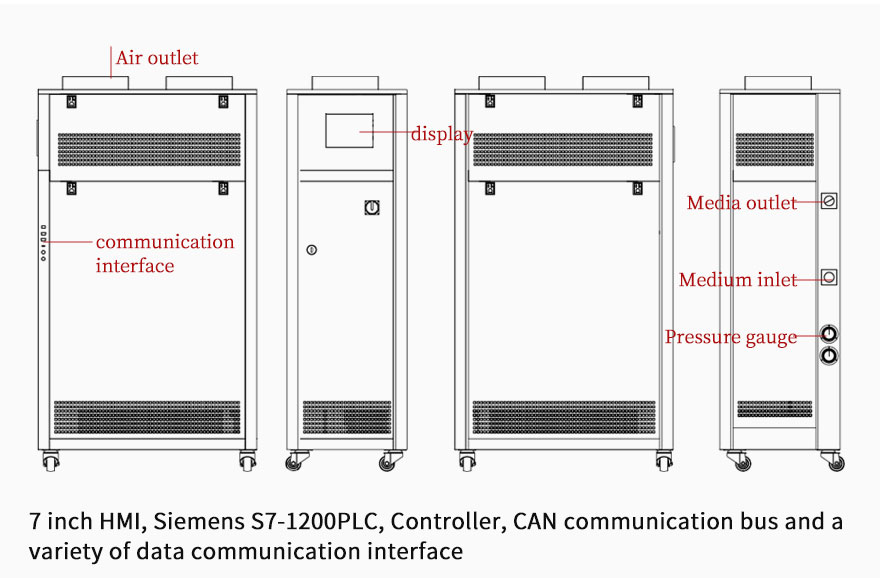

ALL automotive chillers model

KRY -40℃~100℃

battery chillers

water-cooling & air-cooling

Heating capacity 2.5kW~60kW

Cooling capacity 1.2kW~60kW

Temp accuracy ±0.3℃

KRYZ -40℃~100℃

antifreeze cooler

water-cooling & air-cooling

Heating capacity 2.5kW~38kW

Cooling capacity 1.8kW~60kW

Temp accuracy ±0.3℃

KRY -40℃~100℃ Multi-channel

liquid cooling chiller

water-cooling & air-cooling

Heating capacity 7.5kW~25kW

Cooling capacity 1.8kW~25kW

Temp accuracy ±0.1℃

KRYZ -40℃~50℃

battery pack cooling system

Cooling capacity 0.5kW~10kW

Heating capacity 0.5kW~10kW

Temp accuracy ±0.5℃

KRYO 0℃~160℃

oil chiller

Heating power 15kW~38kW

Cooling capacity 12kW~38kW

Flow rate accuracy ±0.2L/min

Temp accuracy ±0.3℃

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier