Why Do Batteries Need Freezing Tests

Have you noticed the growing number of electric vehicles on the road?

With the development of new energy technology and the improvement of environmental awareness, battery-powered vehicles are now a common sight in daily life.Have you ever wondered why electric vehicles charge more slowly and discharge more quickly in winter? Does this affect the life of the battery? Why do some electric vehicles also have stable performance in an environment of -20℃?

This is closely related to a key step in R&D: the battery low-temperature test. What is the battery low temperature test? Why do you do this? What happens when the battery is frozen? How is the freezing test conducted? This article reveals the mystery of battery testing for you.

Why freeze the battery?

The battery freezing test is to simulate the low temperature environment that may be encountered in actual use. In North America, Northern Europe, Russia and other places, the temperature in winter is very low, which can make it difficult for electric vehicles to start. In cold chain transportation equipment and some polar exploration equipment, the battery system may malfunction or even short-circuit due to low temperatures.

In order to prevent these problems from occurring during use, R&D personnel must understand their performance at low temperatures in advance. Evaluate the cold resistance of materials, the service life of batteries, internal chemical reactions and low temperature critical values.

What happens when the battery is frozen?

How does a battery behave in low-temperature environments? Here are the main effects:

Slow charging

When charging an electric car in winter, it takes a long time to fully charge, because the low temperature affects the charging speed of the battery. At low temperatures, the viscosity of the electrolyte increases, the resistance to the movement of lithium ions in the electrolyte increases, and the charging efficiency of the battery decreases. If charging continues in a low temperature environment, lithium metal deposition may occur, which in turn damages the battery and even causes thermal runaway.

Accelerated discharge

Perhaps you have discovered that the battery power drops a lot after driving an electric car for a short distance in winter. The reason why the battery can supply power is that a chemical reaction occurs inside, converting chemical energy into electrical energy. After the battery is connected to the external circuit, lithium ions will move out from the negative electrode and reach the positive electrode through the external circuit, thus forming a current. At low temperatures, the migration of lithium ions will be hindered, the internal resistance of the battery will increase, the voltage will become lower during discharge, and the available power will be reduced.

Safety hazards

At extremely low temperatures, the electrolyte may crystallize or partially precipitate lithium, or even structural damage may occur, such as bulging, leakage, short circuit, etc. Encountering these problems in a moving car will greatly endanger the life safety of the driver and passengers.

Battery performance at different low temperatures

Batteries have different performance in different low temperature ranges. Testing in different temperature zones can help R&D personnel optimize battery formulas and evaluate the stability of battery cell packaging.

| Temperature Range | Battery Performance |

| 0℃ ~ -10℃ | Slight performance drop, still operational |

| -10℃ ~ -20℃ | Noticeable capacity loss, insufficient starting voltage, shorter discharge time |

| -20℃ ~ -40℃ | Most lithium batteries cannot function properly; requires special low-temperature batteries |

| -40℃ ~ -80℃ | Extreme test range for aerospace, military, and other harsh environment applications |

Battery freezing test standards

In order to verify the reliability of batteries and facilitate comparison and certification, many countries and regions have issued battery freezing test standards.

IEC 62660

The International Electrotechnical Commission issued the IEC 62660 standard in 2010, which applies to all lithium-ion cells used in electric vehicle power systems. It stipulates that battery capacity testing, voltage retention testing and cycle life testing should be carried out at -20°C. The test environment, test methods and qualification standards of batteries are stipulated.

UN 38.3

The United Nations Economic Commission issued UN 38.3 in 1999, and this standard is continuously updated. It applies to all lithium batteries and finished battery packs used for international transportation, including electric vehicles, mobile phones, power tools, etc. The battery must be stored at -40°C±2°C for 6 hours, followed by +75°C±2°C for another 6 hours, repeating the cycle 10 times over 5 days. During the test, the battery does not leak, swell, catch fire, explode, and meet the rated voltage requirements to be qualified.

SAE J2929

The Society of Automotive Engineers (SAE) released SAE J2929 in 2008 and revised it in 2020. This standard applies to battery systems of electric and hybrid vehicles sold in the United States. It requires environmental simulation of the entire battery system, including low-temperature operation, low-temperature charging, and low-temperature failure modes. It is recommended that the test temperature be controlled at -30°C to simulate the North American winter temperature.

NASA-STD-4009

The National Aeronautics and Space Administration (NASA) revised NASA-STD-4009 in 2021. This standard applies to battery systems for spacecraft, satellites, and deep space exploration equipment. It is required to test at -60°C or even lower to evaluate the air tightness, thermal control capability, and electrochemical stability of the battery system at extremely low temperatures.

GB/T 31467

The State Administration for Market Regulation of China released GB/T 31467 in 2015. It applies to lithium-ion power battery systems for electric vehicles. The battery is required to undergo capacity, power, and charge and discharge performance tests at -20°C, and the test method and temperature control box error (±2°C) are specified.

| Standard Name | Country/Organization | Temperature Requirement | Main Application | Release Year |

| IEC 62660 | International / IEC | -20℃ | Performance and safety testing of EV single cells | Since 2010 |

| UN 38.3 | United Nations / UNECE | -40℃ cycling | Transportation adaptability and safety testing of batteries | Since 1999 |

| GB/T 31467 | China | -20℃ | Performance and safety testing of EV battery packs | Since 2015 |

| SAE J2929 | USA / SAE | -30℃ | Safety and performance of battery pack systems | Since 2008 |

| NASA-STD-4009 | USA / NASA | -60℃ and below | Special battery testing for aerospace applications | 2021 Edition |

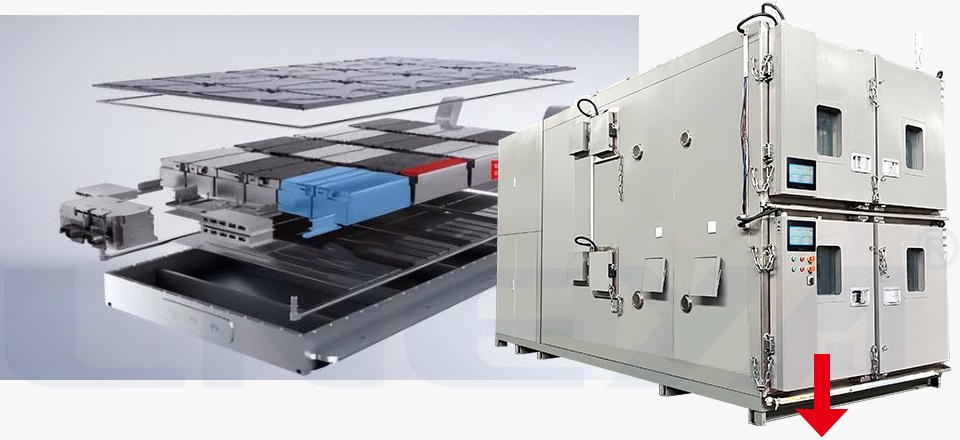

How is the battery freezing test conducted?

The following are the basic procedures and precautions for battery freezing testing.

Prepare samples

It is necessary to select representative cells and battery packs, and inspect the samples carefully to ensure that they are free from obvious defects, such as bulging and leakage.

Record the initial state

For the convenience of comparison, record the initial voltage, resistance, state of charge and other data of the battery. If you want to perform a cycle test, you also need to record the data of the last test.

Set a low temperature environment

According to the corresponding test standards, set the target temperature on the touch screen of the battery test box, which is generally -20 and -40℃. If it is a battery used for aviation, it needs to be set to about -70℃. To avoid thermal shock, you need to set a reasonable cooling rate.

Slow cooling

Place the battery in the test box and close the door, ensuring even thermal conduction through the sample holder. Wait for the temperature in the environmental test box to drop to the target temperature. Avoid frequent opening and closing of the box door during this process.

Maintain constant temperature

After reaching the target temperature, the sample needs to be placed in a constant temperature environment for at least 6 hours according to the requirements of the standard. During this period, the temperature fluctuation curve needs to be recorded to keep the temperature uniformity within ±2℃.

Testing

Perform discharge test, charge test and cycle test under low temperature conditions. Record battery capacity, voltage, internal resistance, discharge rate and other data. Compare with parameters at room temperature.

Heating

After the test, slowly warm the battery to room temperature. It should be noted that the battery do not expose it directly to ambient room temperature, which will cause condensation or thermal stress damage. Then perform a safety check on the battery to check for bulging, leakage and other problems.

Note

• Make sure that the sample battery has no obvious damage

• Do not charge at extremely low temperatures

• Before discharging, it is necessary to maintain a constant temperature for a long enough time to avoid uneven cooling of the battery cell

• Someone must be present during the test

Performance of different types of batteries in freezing tests

Different types of batteries have different performance and behave differently in low temperature environments.

| Battery Type | Low-Temperature Characteristics |

| Ternary Lithium Battery | High energy density but poor low-temp performance; fast capacity fade; suitable for temperate climates |

| Lithium Iron Phosphate (LFP) Battery | High safety, better low-temp performance; can discharge at -20℃, but has lower energy density |

| Solid-State Battery | New battery technology with good low-temp stability; commercialization is still in progress |

| Nickel-Metal Hydride (NiMH) Battery | Significant capacity loss at low temperatures; suitable for low-power devices |

| Sodium-Ion Battery | Under development; early data shows better low-temp performance than traditional lithium batteries |

How to choose a battery test chamber?

If you buy a battery chamber for the purpose of testing electric vehicle batteries, how should you choose? You need to consider the following factors:

| Item | Description |

| Temperature Range | Recommended: -70℃ to +100℃ (covers extreme environments) |

| Temperature Control Accuracy | At least ±0.5℃ (depending on testing standard) |

| Temperature Uniformity | ≤±2℃ to ensure consistent data for multiple battery samples |

| Cooling Rate | Recommended ≥1℃/min; some standards require ≥5℃/min |

| Data Logging | Should automatically record temperature, voltage, time, and other test data |

| Compatibility | Supports battery testers, communication interfaces, gas monitoring modules, etc. |

| Safety System | Equipped with over-temp alarm, power failure protection, leakage detection, etc. |

| After-sales & Customization | Supports customization, fast delivery, and technical consultation |

Conclusion

Battery testing is necessary to ensure the safety of equipment and personnel. Generally, specially designed battery test chambers are used to simulate real-world application environments to test the performance of batteries at different temperatures. If you are looking for a reliable battery test chamber manufacturer, LNEYA is happy to provide you with customized solutions and technical support.

Contact LNEYA today to explore our full range of customized battery test chambers tailored to your specific needs.

Related chillers

CONTACT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Have a question or need a quote? Fill out the form below, and our team will get back to you within 24 hours.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier