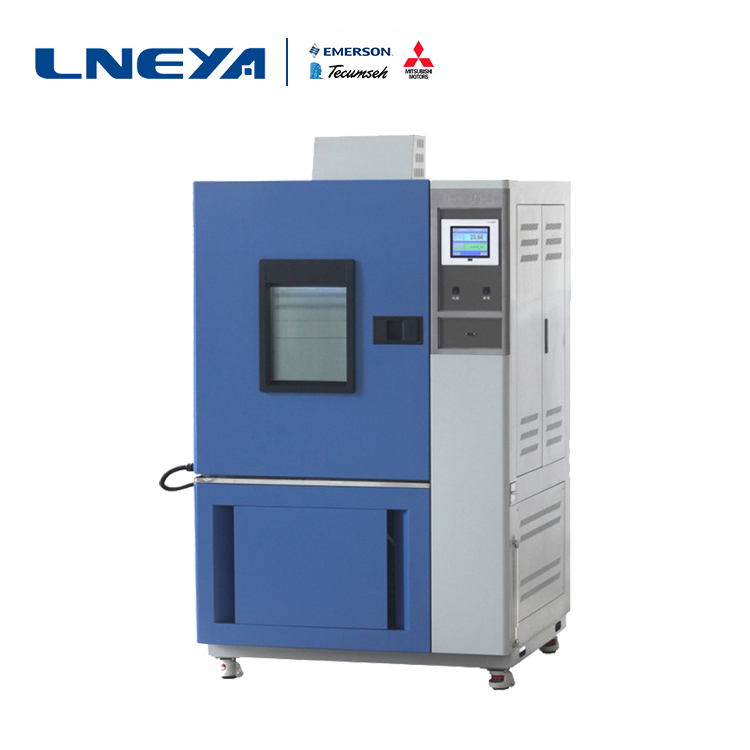

Rapid temperature change test chamber temperature control instructions

The selection of the humidity range of the rapid temperature change test chamber should be noted that the corresponding temperature range should be indicated after the humidity index or the dew point temperature should be given. Because relative humidity is directly related to temperature, for the same moisture content, the higher the temperature, the lower the relative humidity. To achieve high temperature and high humidity, it is only necessary to spray water vapor or atomized water droplets into the air of the cabinet to humidify. Low temperature and low humidity are relatively difficult to control, because the moisture content at this time is very low, and sometimes it is much lower than the moisture content in the atmosphere, and it is necessary to dehumidify the air flowing in the tank to make the air dry.

The common rapid temperature change test chamber generally refers to a constant rapid temperature change test chamber, which is controlled by setting a target temperature and the test chamber has the ability to automatically thermostat to the target temperature point. The control method of the constant temperature and humidity test chamber is similar. Set a target temperature and humidity point. The test chamber has the ability to automatically adjust the temperature to the target temperature and humidity point. The high and low temperature alternating test chamber has the program of setting one or more high and low temperature changes and circulations. The test chamber has the ability to complete the test process according to the preset curve, and can control the temperature rise within the range of heating and cooling rate capability. The rate of temperature drop, that is, the temperature rise and temperature drop rate can be controlled according to the slope of the set curve.

Similarly, the high and low temperature alternating heat and humidity test chamber also has a preset temperature and humidity curve, and the ability to control according to presets. Of course, the alternating test chambers all have the function of a constant test chamber, but the manufacturing cost of the alternating test chamber is higher, because the alternating test chamber needs to be equipped with a curve automatic recording device, a program control device, and the test chamber must be solved in the working chamber. When the temperature is high, the refrigerator is turned on. Therefore, the price of the alternating test chamber is generally 20% higher than the price of the constant test chamber. Therefore, we should be realistic and take the test method as the starting point, choose a constant test box or an alternating test chamber.

Different rapid temperature change test chamber manufacturers have different quality, so users need to understand the rapid temperature change test chamber and make more detailed choices.

Related recommendations

-

Explosion Proof Refrigerator-Suitable for mechanical producing plant

1436LNEYA Explosion Proof Refrigerator is a kind of special refrigerator mainly used for the special industrial environment to keep dangerous goods which are difficult to preserve, volatile and inflammable and explosive. With the development of petrol...

View details -

What are the temperature control performance of laboratory recirculating chillers

1018The laboratory recirculating chiller is atypical cooling circulator with heating function to ensure the repeatability oflaboratory results. There are water-cooled or air-cooled refrigerators, whichcan be placed in a laboratory fume hood or set ...

View details -

The difference between air-cooled and water-cooled 15P refrigeration units

1170Because the demand conditions are different, when the selected 15P refrigeration unit is air-cooled and water-cooled, what is the difference? The air-cooled 15P refrigeration unit contains a heat-insulating water tank and water pump in its body, w...

View details -

What is the temperature control method of the reactor?

884The reaction kettle used for temperature control has a large capacity and a thick wall, so it is a controlled object with a large heat capacity and a long pure lag time. As the reaction progresses, the heat transfer coefficient of each heat transf...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier