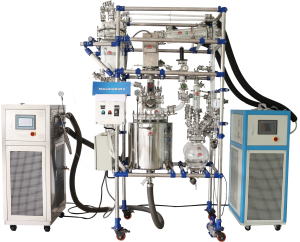

Energy-efficient high and low temperature circulation box description

With the efficient development of the pharmaceutical and chemical industry, environmental pollution is also the subject of more attention. To this end, LNEYA actively responds to environmental protection, produces energy-efficient and high-temperature circulating boxes, and saves enterprise costs as much as possible.

The high and low temperature circulation box group reduces the condensation temperature under the premise of evaporation temperature. In order to meet the safety and production requirements of the equipment, the evaporation temperature is lowered to reduce the condensation temperature, so as to ensure the cooling water efficiency and increase the transformation. Adjust the reasonable operation of the chiller equipment. When the equipment is safely operated, the cooling unit operates at 70%-80% load ratio and runs at 100% load, and the power consumption per unit of cooling capacity is smaller. In this way, it is necessary to combine the operation of the water pump and the cooling tower.

Prevent and reduce pipe fouling to improve the heat exchange efficiency of the condenser and evaporator. Replenish water If the water treatment is not good, calcium carbonate and magnesium carbonate produced by the heating of calcium bicarbonate and magnesium bicarbonate will deposit on the pipeline. Decreasing the thermal conductivity, affecting the heat exchange efficiency of the condenser and the evaporator, and greatly increasing the electricity cost of the equipment. In addition to the water treatment technology, it is also possible to use the pipeline automatic cleaning equipment for pipeline cleaning. The high-low temperature cycle box group refrigerator frequency conversion device adjusts the speed of the centrifugal refrigerator compressor. After the low-pressure refrigerant passes through the centrifuge, the pressure rises. The higher the speed of the centrifuge, the higher the pressure rises. In actual operation, most of the equipment is running at a non-full load. A fixed-speed centrifuge wastes energy when the equipment is running at a small load. The variable frequency centrifugal chiller can automatically adjust the compressor speed according to the change of the load, and the energy saving space is relatively large.

These operating instructions can help the high and low temperature circulation box to be more energy efficient and use as much energy consumption as possible.

Related recommendations

-

Temperature control system for reaction kettle

848The reaction kettle temperature control system is an automated equipment used to precisely control the temperature of materials inside the reaction kettle, widely used in fields such as chemical, pharmaceutical, biochemical, and material sci...

View details -

What are the components that improve the performance of industrial chillers?

1119Industrial chillers are indispensable equipment in LNEYA production. With its normal operation, we will have better work efficiency and higher product quality. The refrigeration system of an industrial chiller is mainly composed of four core compo...

View details -

What are the ways to use the circulating heater for the reactor in the pharmaceutical and chemical i

1117In the pharmaceutical and chemical industry, there are many reactor heaters used in the reactor industry. In the pharmaceutical chemical industry, what other heating methods besides this heating method? The heating method of the reactor circulatin...

View details -

What Industries Can Low Temp Chillers Help?

976Maybe some of you don't know much about low temp chiller products. The low temp chiller is a kind of professional refrigeration equipment used in industrial production. In recent years, there has been a great demand for different types of low temp...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier