Semiconductor Chillers in Packaging: Boost Reliability and Performance

- What Is a Burn In Chamber

- Why Chip Testing Needs Semiconductor Chillers

- Semiconductor Chillers in Chip Testing

- Semiconductor Chillers in Wafer Dicing

- Semiconductor Chillers in Packaging

- How to Upgrade an Old Chiller to Improve Efficiency

- Chiller Tanks Comparison Expansion Tank vs Buffer Tank

- Expansion Tanks in Semiconductor Chillers

- August 2025

- July 2025

- June 2025

- May 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- September 2023

- July 2023

- June 2023

- May 2023

- January 2023

air cooled chiller chiller chillers Cold Assembly Freezer cooling chiller cooling heating circulator cooling heating system cooling water chiller Double-Layer Glass Reactor dynamic temperature control system Fluorinated liquid temperature control freezer gas cooling chiller heating circulator industrial chiller industrial cooling industrial freezer industrial refrigerator jacket reactor liquid cooling chiller low temperature chiller news pharmaceutical chiller process chiller reactor chiller reactor cooling reactor cooling heating reactor heating cooling reactor system refrigerated circulator refrigeration chiller screw chiller semiconductor chiller semiconductor test chiller sundi tcu temperature control test chamber thermostat ultra low temperature chiller vehicle test chiller water chiller water cooled chiller wtd

Semiconductor packaging may look like the “final wrap” of the chip, but in reality, packaging is one of the critical steps that determines reliability, performance, and long-term yield.And here’s the catch—packaging is all about managing heat.

Whether it’s bonding wires, curing underfill, or molding epoxy, temperature control can make or break the process. This is where semiconductor chillers come into play. They may not get the spotlight, but without them, most modern packaging lines would struggle to keep yields consistent.

What is Semiconductor Packaging?

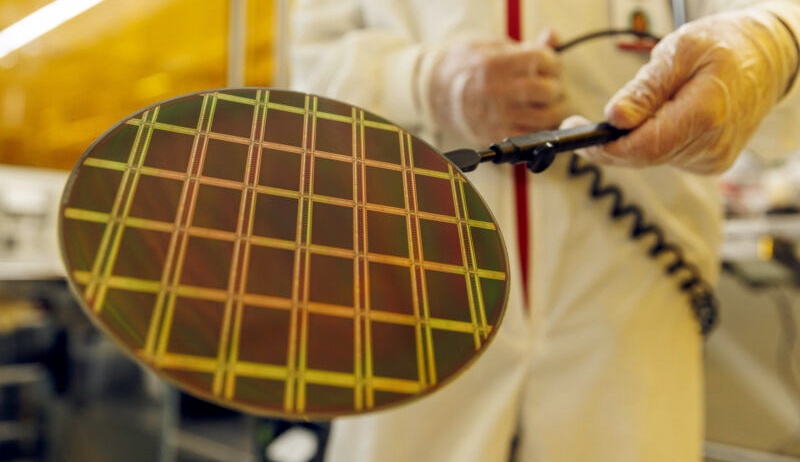

Semiconductor packaging is the step where a bare silicon die is turned into a functional chip that can be mounted on a circuit board. Think of it as building a protective housing while also creating the electrical connections between the wafer and the outside world.

Packaging covers a wide range of processes, including:

• Die attach – mounting the chip onto a substrate with adhesive or solder.

• Wire bonding or flip chip – making the electrical connections.

• Encapsulation and molding – covering the chip with protective material.

• Final testing and burn-in – ensuring the device works under stress.

Every one of these steps relies on precise thermal conditions. A little too hot, and materials expand, warp, or crack. Too cold, and adhesives won’t cure properly, and bond strength drops. That’s why fabs invest so heavily in environmental control systems. Packaging is not just about “sealing” the chip—it’s about controlling energy transfer at microscopic levels.

Temperature Challenges in Semiconductor Packaging

If you ask any packaging engineer what keeps them up at night, chances are the answer is “thermal management.” Heat shows up in unexpected ways.

Die Attach

Take die attach, for example. Attaching a chip with epoxy looks simple enough, but the adhesive has a very specific temperature profile. If the heating is uneven, tiny voids form inside the joint. Those voids later become failure points when the chip heats up during real-world operation.

Wire Bonding

Wire bonding is another delicate process. When gold or copper wire is bonded onto aluminum pads, the interface needs just enough heat to create a reliable bond. Too much, and the bond pad lifts off. Too little, and the bond won’t hold through thermal cycling.

Flip Chip Packaging

Flip chip packaging adds even more complexity. Reflow solder bumps are extremely sensitive to both heating and cooling rates. Cooling too quickly can trap stress in the bumps, while cooling too slowly may cause uneven joints.

Molding and Encapsulation

And then there’s molding and encapsulation. Epoxy resins cure through exothermic reactions. As they harden, they release heat. If that heat isn’t pulled away fast enough, the resin cures unevenly, leading to internal stress and package warpage. Even a slight bow in a package can prevent it from being mounted properly on a circuit board later.

These challenges explain why packaging facilities need something far more precise—tools that can hold liquid temperatures within fractions of a degree, 24/7.

Why Semiconductor Chillers Are Essential in Packaging?

This is where semiconductor chillers prove their value. They don’t just “cool things down.” They provide tight, repeatable, and reliable temperature control across multiple packaging stages.

Stable Temperature for Die Attach

During die attach, whether with silver epoxy or solder, the bonding stage requires consistent thermal conditions. A semiconductor chiller ensures the adhesive cures at the right speed and uniformity.

That reduces the risk of voids and improves long-term device reliability. For high-power chips, where die attach quality directly impacts thermal resistance, the role of the chiller is even more critical.

Precision in Wire Bonding and Flip Chip Processes

Bonding machines are sensitive to even the smallest temperature drift. The spindle, bonding capillary, and stage all expand when they heat up. A chiller prevents this drift by keeping the chilled water or stage liquid at a stable temperature. In flip chip, semiconductor chillers regulate reflow profiles and maintain cooling ramps that protect solder joints from cracking.

Cooling During Molding and Encapsulation

In molding, a chiller removes the excess heat generated by epoxy curing. Without precise cooling, packages may warp or show internal cracks. Chillers allow mold presses to operate faster and more consistently, because the cooling step becomes predictable and repeatable. This not only saves cycle time but also improves package flatness.

Supporting Reliability Testing

After packaging, chips undergo reliability tests such as thermal cycling, burn-in, or humidity bias tests. Many of these require rapid temperature shifts. Chillers integrate with thermal chambers to provide stable and repeatable conditions, ensuring that testing results reflect actual product performance.

Investing in Reliable Semiconductor Chiller

Heat is both necessary and dangerous—it enables bonding and curing but threatens yield if uncontrolled. Semiconductor chillers give fabs the stability needed to manage this balance.

They stabilize die attach, keep bonding precise, pull heat from molding processes, and support critical reliability tests. More than that, they help fabs protect their investment in wafers and equipment while ensuring products make it to market without hidden weaknesses.

Contact our team today to explore customized chiller solutions for your fab.

Related chillers

CONTACT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Have a question or need a quote? Fill out the form below, and our team will get back to you within 24 hours.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier