Thermal Oils Commonly Used in Chillers

- How to Upgrade an Old Chiller to Improve Efficiency

- Chiller Tanks Comparison Expansion Tank vs Buffer Tank

- Expansion Tanks in Semiconductor Chillers

- How Explosion-Proof Chillers Work Principles and Design

- August 2025

- July 2025

- June 2025

- May 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- September 2023

- July 2023

- June 2023

- May 2023

- January 2023

air cooled chiller chiller chillers Cold Assembly Freezer cooling chiller cooling heating circulator cooling heating system cooling water chiller Double-Layer Glass Reactor dynamic temperature control system Fluorinated liquid temperature control freezer gas cooling chiller heating circulator industrial chiller industrial cooling industrial freezer industrial refrigerator jacket reactor liquid cooling chiller low temperature chiller news pharmaceutical chiller process chiller reactor chiller reactor cooling reactor cooling heating reactor heating cooling reactor system refrigerated circulator refrigeration chiller screw chiller semiconductor chiller semiconductor test chiller sundi tcu temperature control test chamber thermostat ultra low temperature chiller vehicle test chiller water chiller water cooled chiller wtd

Thermal oil (also known as heat transfer fluid) is a liquid used to transfer heat and is used in the cooing circuit of industrial chillers. Compared to pure water and glycol, it has a wider operating temperature range and more stable physical properties. The right thermal oil can improve the heat transfer efficiency of cooling systems and help extend the life of equipment. This article explains common thermal oils and how to choose one.

Thermal oil is generally categorized into two main types: synthetic oil and mineral oil.

Synthetic Thermal Oil

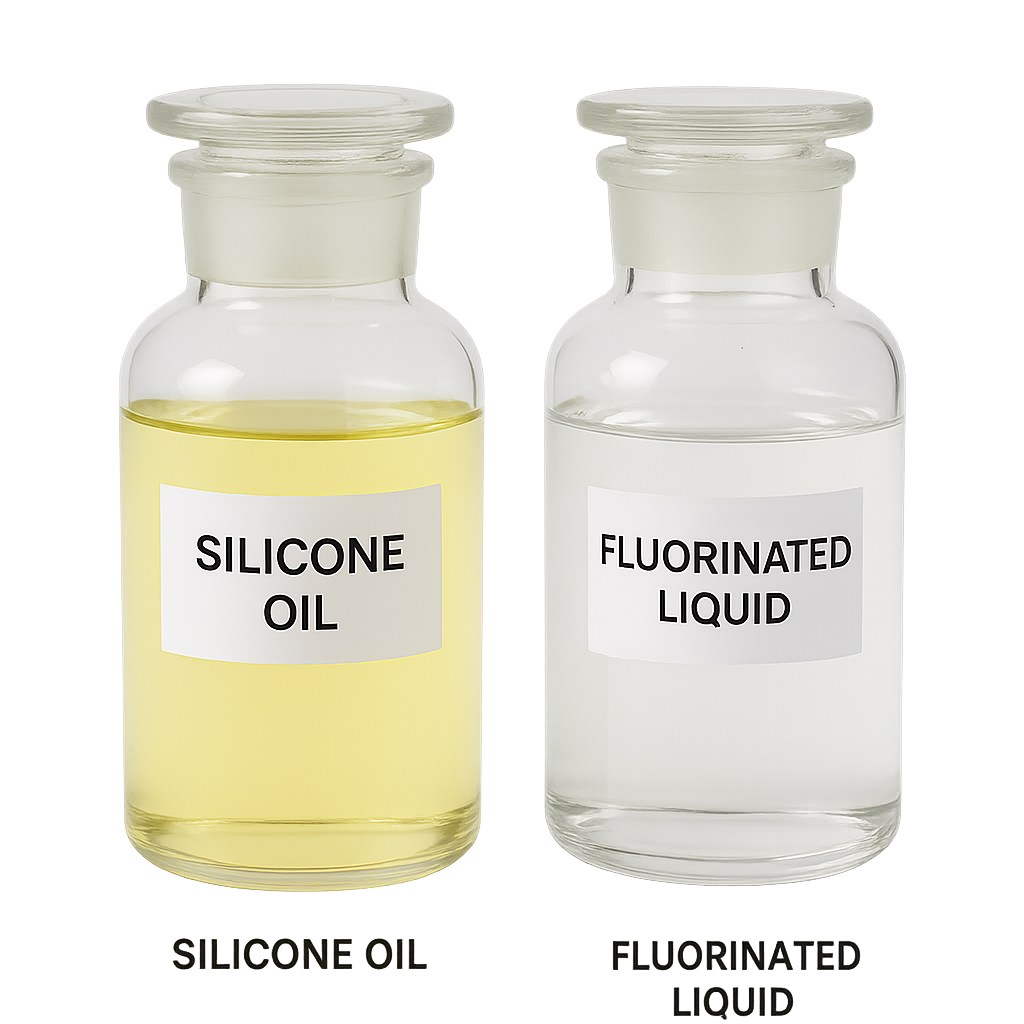

Common synthetic thermal oils used in chillers include silicone oil, fluorinated liquid, biphenyl/diphenyl ether blend, and synthetic aromatic hydrocarbon-based oil. These are synthesized from a variety of chemical substances and offer improved thermal and oxidative stability, as well as reduced volatility. They are used in circulating cooling and heating systems operating in various temperature ranges.

Silicone Oil

Silicone oil is clear and water-like in appearance, but has an oily, lubricating feel. Its greatest feature is its resistance to both heat and cold. Most silicone oils operate normally between -80°C and +250°C, making them ideal for process chillers that require alternating hot and cold cycles.

Furthermore, it doesn’t evaporate easily at high temperatures, with no visible oil mist formation in closed-loop systems and enabling longer circulation times. Many users worry about its corrosive properties on pipes. Don’t worry!It won’t corrode or deform either metal or plastic pipes. Furthermore, it’s non-conductive, making it safe for use in equipment with internal circuitry.

However, it’s relatively expensive and conducts heat more slowly than other thermal oils. For general applications with limited temperature fluctuations and limited cost, it’s not our top recommendation.

Fluorinated liquid

Fluorinated liquid is a high-end coolant designed for extreme temperature environments. It flows well and looks like water, but it’s actually a special liquid modified with fluorine. It’s highly stable and safe, and some fluorinated liquids can operate continuously in temperatures between -100°C and +200°C.

Furthermore, because it’s non-conductive, leaks won’t cause short circuits, making it ideal for use in equipment with circuitry or chips. Furthermore, it won’t react with metal or plastic to form deposits over time. Some fluorinated fluids, such as 3M’s Novec™ series, are considered environmentally safer alternatives to traditional oils.

While fluorinated liquid offers excellent performance, it’s also very expensive, costing dozens of times more than ordinary thermal oil. Therefore, it’s often used in cooling equipment for semiconductor chillers, aerospace testing equipment, and precision instruments.

Biphenyl/diphenyl ether blend

Biphenyl and diphenyl ether are very stable at high temperatures and are often combined to form an azeotropic blend for stable thermal performance, such as Dowtherm A. Its operating temperature generally ranges from 12°C to 400°C, and it can operate effectively in both liquid and vapor phases, making it commonly used in chillers with high operating temperature limits.

Similar to the two thermal oils mentioned above, it is not susceptible to decomposition or deterioration at high temperatures. It is generally used in closed systems to avoid contact with air, which may affect its service life.

Synthetic aromatic hydrocarbon-based oil

Synthetic aromatic hydrocarbon-based oil, primarily composed of compounds containing benzene rings, is both heat-resistant and low-volatility, making it a common choice in modern process chillers. Its operating temperature generally ranges from -20°C to 350°C, but some models can also operate at moderate to low temperatures. It has excellent oxidation stability and does not deteriorate as rapidly as mineral oil, even with minimal air contact.

Mineral Thermal Oil

Mineral thermal oil is extracted from petroleum through a filtering, dewaxing, and refining process. It was an early form of thermal oil, and despite the advent of more advanced synthetic thermal oils, it is still used by many factories due to its low cost and availability. Common mineral thermal oils used in industrial chillers are paraffinic mineral thermal oil and aromatic mineral thermal oil.

Paraffinic Mineral Thermal Oil

Paraffinic mineral thermal oil resembles a cleanly processed petroleum grease and is favored by many users for its low odor, high stability, and low volatility. It is generally used in systems operating between -10°C and 300°C. Due to its high viscosity at low temperatures and the risk of thermal cracking and degradation at high temperatures, it is not typically used in ultra-low and ultra-high temperature chillers. It is less expensive than both aromatic and synthetic mineral thermal oils.

Aromatic Mineral Thermal Oil

Aromatic mineral thermal oil is extracted from the aromatic components of petroleum. It has greater heat resistance and can withstand operating temperatures up to 300°C, making it suitable for use in high-temperature equipment. Under the same cooling conditions, its heat transfer efficiency is higher than that of Paraffinic Mineral Thermal Oil, and it circulates smoothly even at low temperatures. However, it has an aromatic ring, which can produce a strong odor at high temperatures.

Common Thermal Oil Products Table

| Category | Product Name | Brand | Key Features |

| Silicone Oil | 200 Fluid | Dow Corning | Multiple viscosities; excellent thermal stability |

| SF Series | Momentive | Suitable for high/low-temp electronic cooling | |

| KF Series | Shin-Etsu | Widely used in industrial chiller systems | |

| AK Series | Wacker | Ideal for heating-cooling cycling systems | |

| Fluorinated Liquid | Novec™ 7100 / 7200 | 3M | Eco-friendly, non-conductive, electronics-safe |

| Fluorinert™ FC-72 | 3M | Ultra-low temperature; used in electronics cooling | |

| Vertrel® XF | Chemours | High safety, excellent stability | |

| Galden® HT55 / HT70 | Solvay | High-temperature performance, inert | |

| biphenyl/diphenyl ether blend | Dowtherm™ A | Dow | High-temp azeotropic mixture |

| VP-1 | Therminol | Liquid/vapor phase, for closed-loop high-temp use | |

| E | Globaltherm | Long-life, high-temp thermal fluid | |

| Synthetic Aromatic Hydrocarbon Oil | Therminol® 66 | Eastman | Stable up to 350°C; industrial standard |

| Xceltherm® 600 | Paratherm | High thermal stability, mid-high temp use | |

| Omnitech | Globaltherm | Excellent oxidative stability | |

| Paraffinic Mineral Oil | Mobiltherm® 603 | Mobil | Good for moderate temperatures, low volatility |

| Heat Transfer Oil S2 | Shell | Refined paraffinic base, widely applicable | |

| Calflo™ AF | Petro-Canada | General-purpose paraffinic oil | |

| Aromatic Mineral Oil | Transcal® N | BP | Aromatic base, efficient heat transfer |

| M | Globaltherm | Oxidation resistant, medium-high temp applications | |

| Thermic Fluid 300 | Multiple Brands | Designed for industrial closed systems |

How To Select a Thermal Oil

When choosing a thermal oil, it’s important to consider the equipment’s operating temperature, oil compatibility, safety, and affordability. Some thermal oils cannot operate properly at low or very high temperatures, so the choice should be tailored to the chiller’s operating temperature.

Furthermore, to prevent the oil from reacting with the piping material and corroding it, leading to leaks, it’s important to choose an oil that is compatible with the chiller. Also, pay attention to the oil’s flash point. For example, mineral oil has a lower flash point and is a fire hazard at high temperatures, while silicone oil and fluorinated fluids perform better in this regard.

Regarding cost, consider purchase cost, replacement cycle, system maintenance costs, and energy efficiency, not just price alone. Some thermal oils, while more expensive, offer longer lifespans and superior performance, making them more cost-effective for long-term projects.

Conclusion

The choice of thermal oil affects the heat exchange efficiency and operational stability of your cooling equipment. If you’re unsure how to choose the right oil for your cooling system, LNEYA is happy to help. We offer customized chillers with various performance characteristics and sell a variety of thermal oils.

Related chillers

CONTACT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Have a question or need a quote? Fill out the form below, and our team will get back to you within 24 hours.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier