Core Maintenance Points of Ten High and Low Temperature Test Chamber Manufacturers

According to many years’ production experience of high and low temperature test chamber in Wuxi Guanya, it is found that many users are not very familiar with the maintenance of high and low temperature test chamber. As one of the top ten manufacturers of high and low temperature test chamber, Wuxi Guanya has sorted out the relevant maintenance points, and everyone pays attention to the analysis.

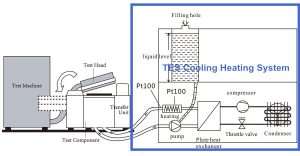

Enterprise users need to have a comprehensive understanding of the products of ten manufacturers of high and low temperature test chamber before choosing. Because of the lack of correct judgment and sufficient recognition, enterprises can not choose high-quality high and low temperature test chamber. Among them, compressors, controllers, electronic devices, boxes and hardware fittings are very important, so the role of each component is very important and nursing is very important.

Cleaning of waterway and humidifier

If the waterway of the high and low temperature test chamber is not smooth, the scaling of the humidifier will easily lead to the dry burning of the humidifier, which may damage the humidifier. Therefore, the high and low temperature test chamber must be cleaned regularly for the waterway and the humidifier.

Selection of Test Environment

Generally speaking, the box of high and low temperature test chamber is relatively high. Ten manufacturers of high and low temperature test chamber suggest that it should be placed in a benign temperature environment when using. For laboratories that do not meet this requirement, it is necessary to equip with appropriate air conditioners.

Clean evaporator regularly

Many small particles such as dust will condense on the evaporator under the forced air circulation of the test sample in the high and low temperature test chamber. It needs to be cleaned regularly in the high and low temperature test chamber, otherwise it will seriously affect the normal use of the equipment.

Clean condenser regularly

The common high and low temperature test chamber usually uses air-cooled cooling compressor, so it is necessary to repair the condenser fan regularly and remove the dirt and dust from the condenser so as to obtain good ventilation and heat transfer performance.

These high and low temperature test chamber ten manufacturers collated the relevant maintenance knowledge, you can pay attention to check the early formulation of maintenance plan.

Raccomandazioni correlate

-

Descrizione del sistema di alimentazione+strumento di controllo elettronico della cella frigorifera a bassissima temperatura LNEYA

1153La cella frigorifera a bassissima temperatura LNEYA deve essere testata dopo un lungo periodo di utilizzo. A cosa bisogna prestare attenzione quando si ispezionano l'alimentazione e il sistema di strumenti di controllo elettronico? LNEYA ultra-low temperature cold box alimentazione e...

Visualizza i dettagli -

The significance of temperature in IC testing

1470Every integrated circuit (IC) goes through two type of tests before it can be sold and used to build a product: the first is called a wafer test; the second is called final test. With the improvement of integrated circuit electrical test technolog...

Visualizza i dettagli -

What Is the Range of Industrial Chiller Temperature Control

1552Industrial chiller is a common refrigeration equipment in industrial refrigeration industry,whose feature is various types, complete models and wide range of applications.More importantly, the precision of chiller temperature control is high and t...

Visualizza i dettagli -

Come scegliere il prezzo del sistema a temperatura costante per semiconduttori?

1143Now, it can be said that most of the industrial productions require semiconductor constant temperature systems to provide professional refrigeration. An efficient semiconductor constant temperature system can provide great help for various industr...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore