News

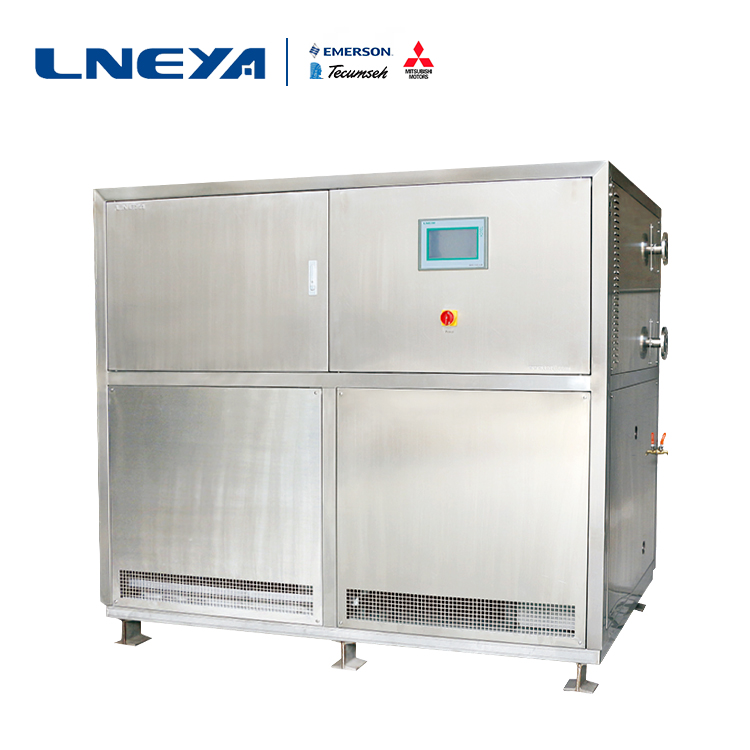

LNEYA bearing freezer refrigeration principle description

LNEYA industrial freezer can be used in the refrigeration process of the bearing industry. Since the use of bearing freezer is relatively large, the performance is very important, so let's talk about the principle today. The refrigerant in the bearing freezer circulates in the refrigeration system under the action of the mechanical energy generated by the compressor, and is repeatedly operated in a gaseous state or a liquid state. During this process, the refrigerant continuously absorbs the ...

View details

Closed circulation cooling system debugging attention note

Closed circulation cooling system needs to pay attention to some common problems during commissioning. Do a good job in debugging work. LNEYA manufacturers remind users that only when they are ready to work can they be better debugged. The preparation work before the commissioning of the closed circulation cooling system is an important part of the debugging process, which may affect the progress of the whole debugging process. Generally, it is necessary to pay attention to the leakage detect...

View details

Explosion-proof high temperature and low temperature machine factory note

Explosion-proof high and low temperature integrated machine is the main product of LNEYA production and sales. It adopts dynamic temperature control system and fully closed pipeline design. The operation effect is relatively stable. What common problems should be paid attention to during the operation? Explosion-proof high and low temperature integrated machine should be installed away from heat source, no direct sunlight, good ventilation, and the ambient temperature should not exceed 35 °C ...

View details

The principle of LNEYA chiller

Industrial chillers are commonly used to cool products and machinery for a variety of different applications, including injection molding, tools and die cutting, food and beverage, chemicals, lasers, machine tools, semiconductors and more. In most process cooling applications, the pumping system circulates cold water or water/glycol solution from the chiller to the process. This cooled fluid removes heat from the process and the warm fluid returns to the cooler. Process water is a means of tr...

View details

How to clean air control system?

In order to respond to the requirements of the two types of society in the country, environmental protection and conservation have become increasingly important. Therefore, in order to extend the life of the product, it is still necessary to have some knowledge of maintenance, and the most important thing to maintain is to say clean. Here, Guanya Refrigeration introduces some small methods for cleaning the air cooling system:More traditional methods are scraping and brushing. Sweep the place ...

View details

Organic waste gas treatment device noise description

With the increasingly stringent environmental requirements, various manufacturers have paid more and more attention to their own organic waste gas treatment. LNEYA organic waste gas treatment equipment specializes in the treatment of various organic waste gases and promotes continuous optimization of environmental protection issues. In the internal structure of the organic waste gas treatment device, the compressor is the core position. Generally, the compressor has two types of compressors, ...

View details

Organic waste gas recovery unit refrigeration oil requirements description

The organic waste gas recovery device is slightly different for different gases. The LNEYA organic waste gas recovery device and the vocs gas condensation recovery device are operated by the principles of condensation and adsorption. The refrigeration oil is also important, then the refrigeration oil has What is the requirement? The cloud point of the frozen oil of the organic waste gas recovery device refers to the temperature at which the paraffin is precipitated in the frozen oil and the l...

View details

Vocs gas condensation recovery unit processing instructions

With the continuous inspection of environmental protection, Wuxi LNEYA VOCS gas condensation recovery device has also received continuous attention from the public. Most chemical, pharmaceutical and industrial industries are urgently dealing with vocs gas. The so-called VOCS is a volatile organic compound, and its composition generally includes an alkane, an olefin, an aromatic hydrocarbon, a halogenated hydrocarbon, an oxygenated hydrocarbon, a nitrogen hydrocarbon, a sulfur hydrocarbon, a l...

View details

How to deal with organic waste gas treatment refrigerant leakage?

In the process of organic waste gas treatment, if it is found that the refrigerant leaks, it is recommended to treat it in time. LNEYA organic waste gas treatment professional manufacturer then analyzes the knowledge of organic waste gas treatment refrigerant leakage. Organic waste gas treatment VOCS gas single material or multi-material condensation recovery, the main treatment gases are: hydrocarbons such as gasoline, crude oil, fuel oil, kerosene, diesel, heavy oil, mixed hydrocarbons; aro...

View details

Vocs equipment industry heat exchanger type description

Every accessory in the vocs device has its function, so every accessory in the vocs device can't be less. So what is the heat exchanger in the Wuxi LNEYA vocs device? What are the main types? Tank heat exchanger: Compared with the traditional heat exchanger, the tank heat exchanger has high heat exchange efficiency, small volume, convenient water circulation, water inlet at the bottom of the waterway, easy drainage, and can effectively reduce dirt. Moreover, the tank heat exchanger can be use...

View details LNEYA Industrial Chillers Manufacturer Supplier -

LNEYA Industrial Chillers Manufacturer Supplier -