Temperature control unit necessary for Chinese medicine chemical raw material extraction-TCU

The production process of traditional Chinese medicine raw materials is relatively complicated: long process, many pipelines, and complicated operations; and most of the preparation raw materials are unstable, such as high environmental parameters such as temperature, humidity, and light, and related raw materials are mostly flammable and explosive. Unlike the preparation product process, the production process of traditional Chinese medicine raw materials is mostly a cross-fusion process of chemical and physical, such as product discoloration, extraction and adsorption. Because the production of traditional Chinese medicine raw materials pays attention to the control of process parameters and environmental parameters, such as light, temperature, and pressure.

The following examples illustrate the different ingredients that can be extracted from the same traditional Chinese medicine ingredients at different temperatures. Such as 1. Add angelica or astragalus powder or angelica and astragalus powder to ethanol, extract at 60~100 ℃ for 1~4h, cool to room temperature, centrifuge to take supernatant, complete one extraction; the number of extraction is 1~4 times. Mix Angelica sinensis with ethanol according to the material ratio of 5~8g/mL, the concentration of ethanol is 40~80wt%, extract at 80 ℃ for 1~2.5h, cool to room temperature, centrifuge and take the supernatant to complete one extraction; extraction times For 1-4 times, extract ferulic acid. 2. Mix Astragalus powder and ethanol according to the material ratio of 12g/mL, the concentration of ethanol is 70wt%, extract at 70 ℃ for 2h, and extract the glycosides. Astragalus powder and ethanol were mixed according to a material ratio of 12g/mL, the concentration of ethanol was 70wt%, and extraction was carried out at 80 °C for 2h to extract flavonoids.

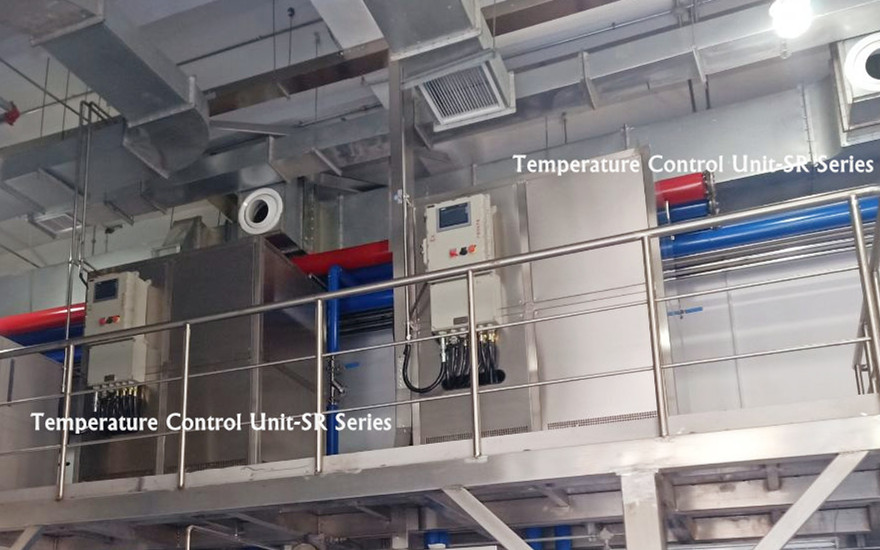

The temperature control unit (TCU) is mainly used for reactor heating and cooling temperature control in the processes of fine chemistry, chemical pharmacy and biopharmaceuticals. It can realize the automatic control of heating, cooling, constant temperature and distillation during the reaction process, especially suitable for the reaction process. There is a process control that requires heat and heat.

When the TCU temperature control unit is in an efficient operation state, it must pay attention to timely protection and maintenance. If the equipment is actively operated in the presence of defects, the life of the equipment will be longer. TCU use range: It can be various explosion-proof areas. Because many pharmaceutical ingredients are flammable and explosive.

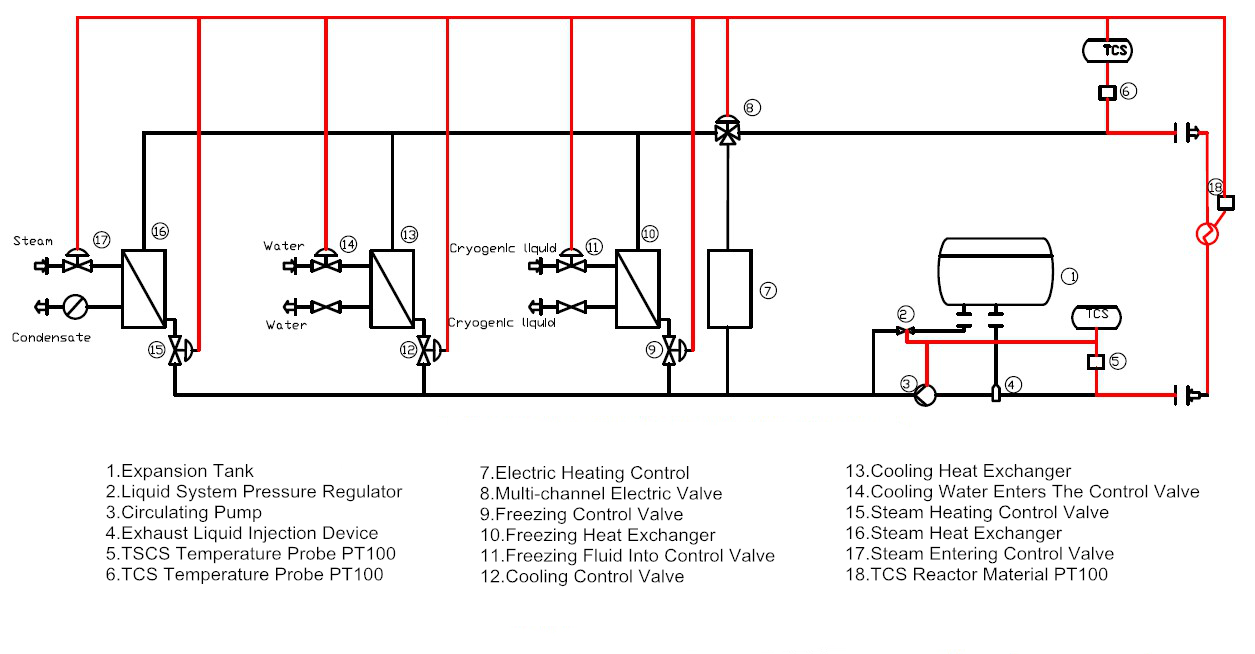

The TCU device opens the angle of the electric regulating valve according to the instruction of the system PLC, and controls the flow of low-temperature liquid entering the reaction jacket, thereby achieving energy saving and high efficiency. All signals fed back by this process are based on temperature.

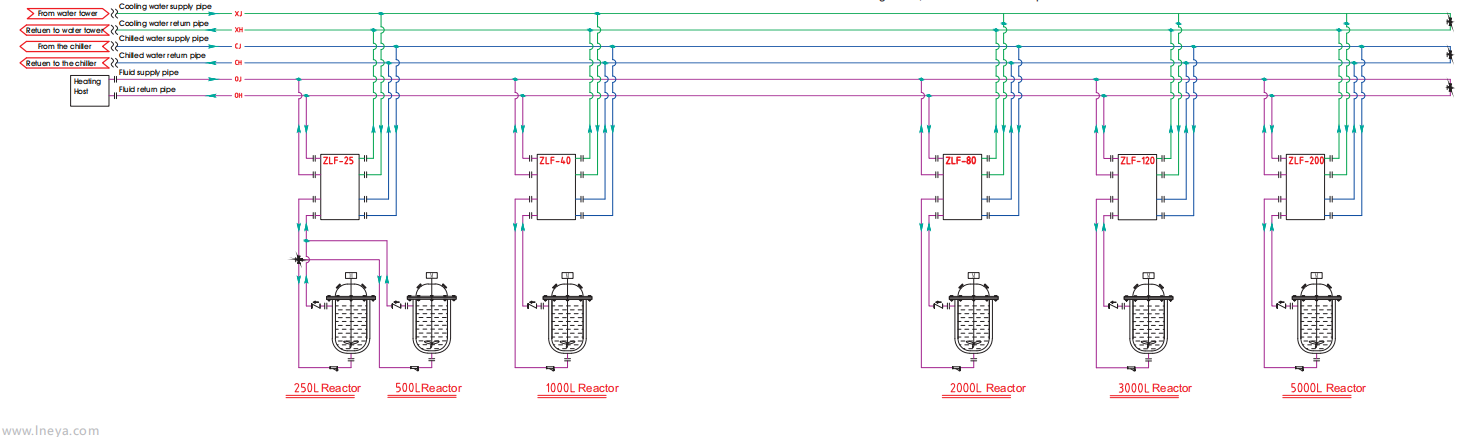

Use existing thermal energy (such as steam, cooling water, and ultra-low temperature liquids-that is, “primary systems”) infrastructure to integrate into a single fluid system or secondary circuit used to control the temperature of process equipment. This completes the flow of only one heat-conducting liquid into the jacket of the reaction vessel (rather than direct steam, cooling water, or ultra-low temperature liquid). The temperature of the whole reaction process is controlled by operation.

Advantages of using single fluid heat transfer temperature control system TCU:

A. The user can obtain a closed and repeatable temperature control in a wide temperature range, which can achieve a temperature control of -120 degrees to 300 degrees;

B. The need to replace the traditional equipment and facilities and the maintenance of the jacket is avoided; the smaller fluid volume also ensures the rapid response of the control loop and the thermal reaction delay is very small;

C. Built-in auxiliary system of electric heating and heat conduction oil, which can automatically turn on the auxiliary heating system according to the demand and reduce the steam use pressure;

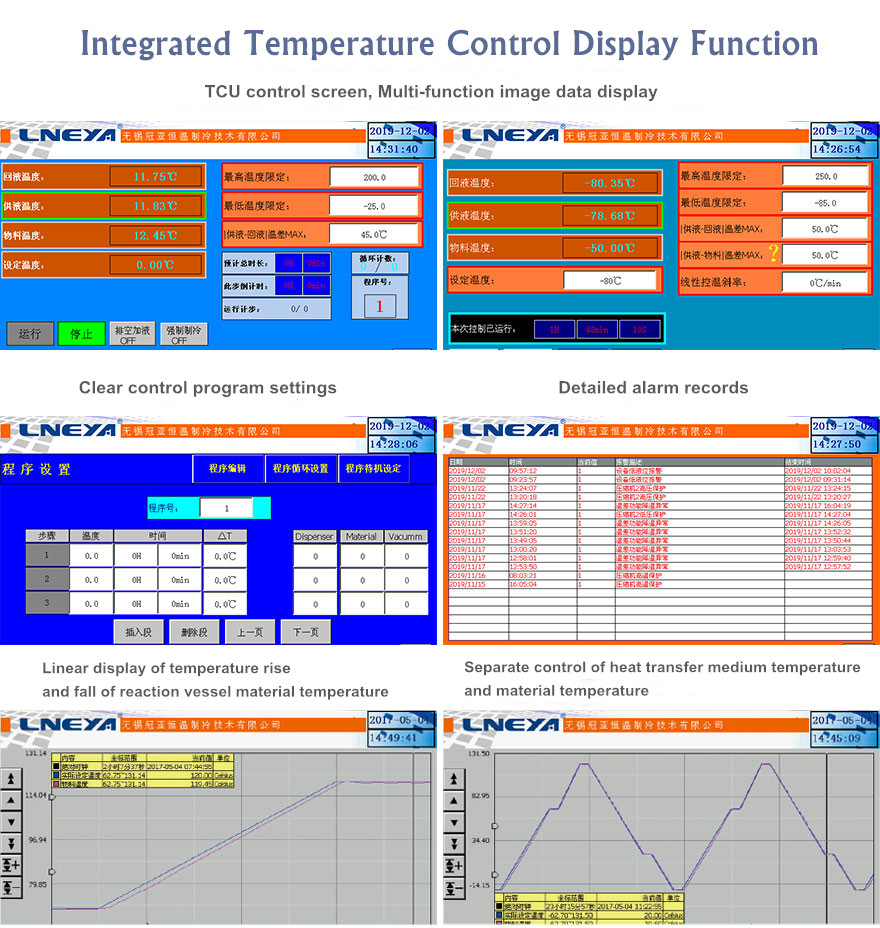

D. Control the temperature of the entire reaction process through accurate and fast calculation, and perform rapid response control for the exothermic and endothermic reactions that occur during the entire reaction process;

E. Standard interfaces are reserved, and heat and cold source heat exchange modules can be added according to actual needs;

F. The temperature of the reaction process and the temperature of the single fluid can be optionally controlled, and the temperature difference between the temperature of the reaction process and the temperature of the thermally conductive single fluid can be set and controlled;

G. Users can conduct recipe management and production process records, and export the data of the reaction control process to the computer for analysis.

Industrial Chillers Manufacturer Supplier - LNEYA

Industrial Chillers Manufacturer Supplier - LNEYA