Unità di controllo termico del reattore e soluzioni per i prodotti chimici

La termoregolazione è un processo in cui la temperatura di una sostanza o una variazione di temperatura viene misurata o altrimenti rilevata, e il trasferimento di energia termica all'interno o all'esterno dello spazio o della sostanza viene regolato per ottenere la temp...

When dealing with pharmaceutical production, maintaining accurate temperature control is critical. Starting with research throughout production, precise temperature control is required at every stage of the process. We fully understand the importance of process cooling, and simple temperature fluctuations (positive and negative) can ruin research or production.

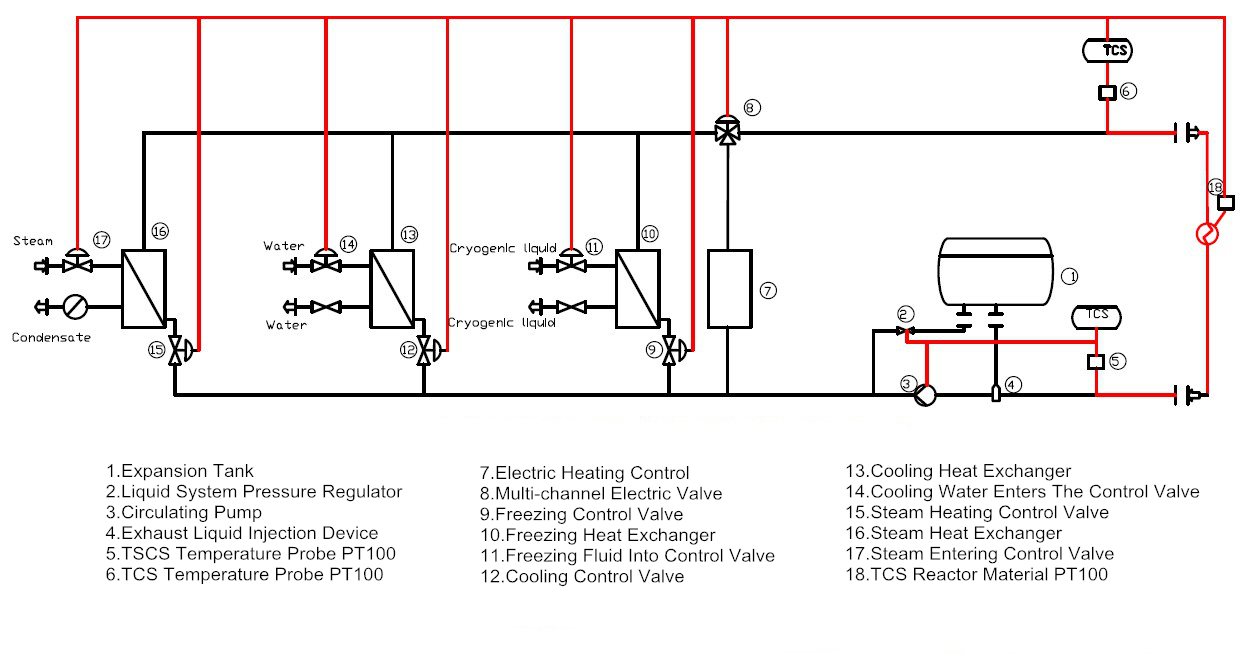

Our TCU can meet all your heating, cooling and temperature control needs for your chemical or pharmaceutical reactor. The LNEYA-TCU temperature control system can utilize existing thermal energy (such as steam, cooling water and ultra-low temperature liquids-the “primary system”) infrastructure integration to achieve dynamic temperature control of the equipment temperature in a single fluid system or a secondary circuit. This only completes the flow of a heat transfer liquid into the jacket of the reaction vessel (rather than directly into the steam, cooling water or cryogenic liquid), and the temperature of the entire reaction process is controlled by calculation.

From -120°C for cryogenic pharmaceutical applications to 300°C for chemical applications, the maximum temperature can be set according to the supplier’s heating or cooling source. The maximum temperature range can be set using a glycol water formula. Through three-point sampling (material temperature point, outlet temperature of temperature control system, inlet temperature of temperature control system), and our own model-free self-building algorithm and general anti-lag cascade algorithm, the problem of large drug delays is solved. Chemical temperature control . Our SR series and ZLF series are completely suitable for low temperature reaction, synthesis, separation process, pilot plant, reactor system, autoclave, combinatorial chemistry, etc.

This will increase product profitability and reactor utilization, and reduce energy and plant operating costs. Our TCU is fully automated and easy to operate. The temperature control accuracy of the product is ± 0.5 ° C, and the cooling power can be provided from 0.5 kW to 1200 kW.

The picture below shows the TCU thermal control unit customized by domestic customers

Raccomandazioni correlate

-

The reason why the cooling water circulator needs the main water circulation

1168The supplement of the water cycle is directed to a water-cooled cooling water circulator, and the air-cooled cooling water circulator does not have this problem. The water-cooled cooling water circulator needs cooling water during normal operation...

Visualizza i dettagli -

Integrated circuit temperature control device research description

961At present, integrated circuit temperature control is used in the integrated circuit, semiconductor, and chip industries. Then, for the testing needs of such industries, integrated circuit temperature control is necessary. At present, there are se...

Visualizza i dettagli -

Manutenzione del sistema di controllo del riscaldamento con raffreddamento a glicole

1105Oltre all'attenzione necessaria durante l'uso quotidiano, anche il controllo e la manutenzione periodica del sistema di controllo del riscaldamento con raffreddamento a glicole sono molto importanti. Per aiutare tutti voi a imparare a utilizzare il riscaldamento a glicole in modo più efficiente, LNEYA...

Visualizza i dettagli -

5L glass reactor thermal oil heating system

7075L glass reactor is a common laboratory equipment used for various chemical reactions. In order to ensure that the reaction is carried out at the required temperature, it is usually necessary to equip it with a heating system. Thermal oil (a...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore