What are the main equipment needed for industrial chillers?

Main equipment of industrial chiller: compressor, condenser, expansion valve, evaporator, chilled water pump, cooling water pump cooling tower (water cooling) Selection: know the required inlet and outlet water temperature, the required cooling capacity, select the corresponding compressor, and then According to the compressor, there are condensers and evaporators.

The chillers and industrial chillers produced by the chiller manufacturers are a kind of refrigeration device that provides chilled water, which can provide chilled water or chemical solutions at -30℃~20℃ according to the needs of users. It is especially suitable for cooling in electroplating, chemical, plastic and other production lines, as well as places where enterprises and institutions need centralized air conditioning or production processes require chilled water.

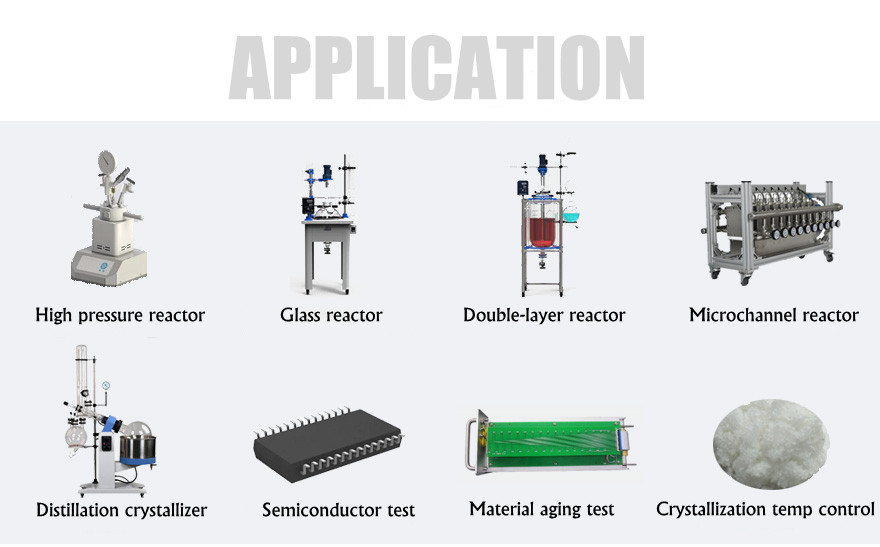

Supporting use of industrial chillers:

1. The chiller manufacturer can use the supporting vacuum equipment. This type of chiller also meets the needs of high-quality vacuum equipment, such as molecular pumps, small vacuum coating machines, etc.;

2. The water chiller can be used with supporting experimental condensing equipment; such as rotary evaporator, distiller, condenser tube, which has the characteristics of controllable temperature, stable temperature, and high condensation efficiency, which can effectively increase the recovery rate; at the same time, its fluid purification function, It can avoid the blockage of the circulation pipeline and the growth of microorganisms;

3. The chiller is used in supporting semiconductor laser equipment; due to its special structure, semiconductor laser equipment has higher water quality requirements; compared with other chillers, chillers and industrial chillers produced by other chiller manufacturers, it has a wide range of applications; except In addition to the refrigeration industry, chillers and industrial chillers are also widely used in other industries such as HVAC, electroplating, metallurgy and smelting, electronics, plastics, and chemical industries. You can see chillers and industrial chillers widely serve. Because of its cross-industry use, the space used by chillers and industrial chillers is relatively large.

Summarize:

The above is an introduction to the use of supporting equipment for industrial chillers, and you can select the appropriate industrial chiller according to the different working conditions of customers. Our lneya has been intensively working in the industry for 15 years and has helped relevant customers in different industries at home and abroad to customize countless temperature solutions. You can contact us by email sales@lneya.com.

Raccomandazioni correlate

-

The Method That Small Water Cooled Chiller Needs To Follow When Charging Refrigerant

1112Nella nostra vita, crediamo che tutti abbiano molta familiarità con la refrigerazione. Nel settore della climatizzazione centrale e dei processi di raffreddamento della produzione industriale, i piccoli refrigeratori raffreddati ad acqua sono più comuni. Questa unità è composta da un compressore...

Visualizza i dettagli -

Introduction to cold plate liquid cooling system products and equipment

1085Introduction to cold plate liquid cooling chiller

Visualizza i dettagli -

Perché un reattore in vetro richiede un refrigeratore e un riscaldatore a circolazione?

790I comuni recipienti di reazione in vetro presenti sul mercato possono essere suddivisi in tre categorie: recipienti di reazione in vetro a pressione negativa, recipienti di reazione in vetro sotto vuoto e recipienti di reazione in vetro agitati ad alta temperatura e ad alta pressione. Il vetro...

Visualizza i dettagli -

Routine maintenance of tcu multi-reactor temperature control equipment

922TCU multi-reactor temperature control equipment is widely used in research departments such as petroleum, chemical, electronic instruments, physics, chemistry, bioengineering, physical property testing and chemical analysis, colleges and universi...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore