Explosion-proof high temperature and low temperature machine factory note

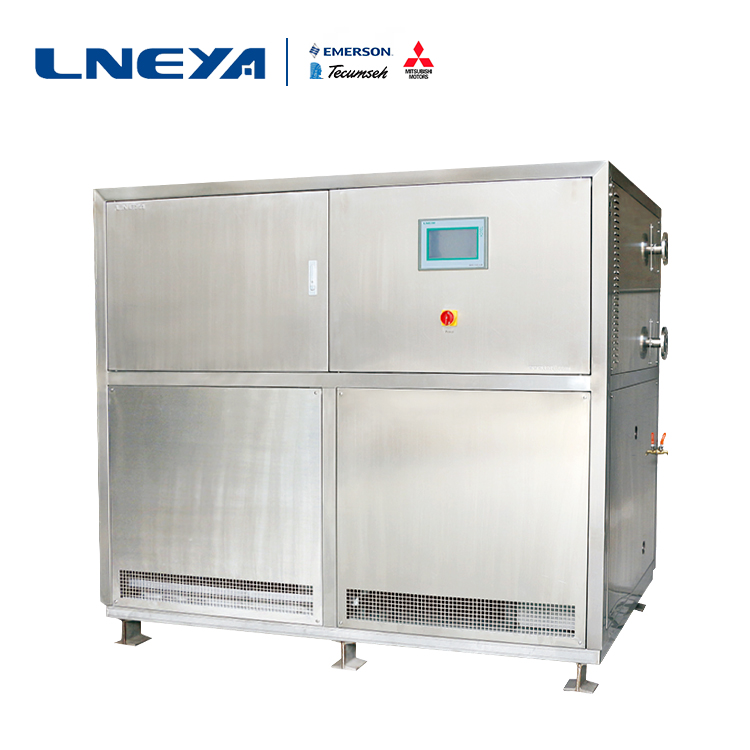

Explosion-proof high and low temperature integrated machine is the main product of LNEYA production and sales. It adopts dynamic temperature control system and fully closed pipeline design. The operation effect is relatively stable. What common problems should be paid attention to during the operation?

Explosion-proof high and low temperature integrated machine should be installed away from heat source, no direct sunlight, good ventilation, and the ambient temperature should not exceed 35 °C to prevent the condenser from dissipating heat and affecting the ice making effect. The installed floor should be solid and flat and must be level, as this will result in no ice detachment and noise during operation.

The explosion-proof high and low temperature integrated machine has a gap of not less than 30cm on the back and left and right sides, and the top clearance is not less than 60cm. Explosion-proof high and low temperature integrated machine should use independent power supply, special line power supply and equipped with fuse and leakage protection switch, and must be grounded reliably. Water should meet the national drinking water standards, and a water filtration device should be installed to filter impurities in the water to avoid clogging the water pipes, polluting the water tank, and affecting the cooling performance.

When cleaning the explosion-proof high and low temperature integrated machine, the power should be turned off. It is strictly forbidden to use the water pipe to directly align with the body. Use neutral detergent to scrub. Do not use acidic or alkaline corrosive solvents. It is necessary to unscrew the inlet hose head two months and clean the inlet valve screen to prevent the sand mud impurities from clogging the water inlet, which causes the water intake to become smaller, resulting in no refrigeration. Explosion-proof high and low temperature integrated machine must clean the surface of the condenser every two months, and poor condensation and heat dissipation will cause damage to the compressor components. When cleaning, use a vacuum cleaner, a small brush, etc. to clean the condensed surface oil dust. Do not use a sharp metal tool to clean it to avoid damaging the condenser.

Water pipes, sinks, storage refrigerators and protective film should be cleaned every two months. When not in use, it should be cleaned, and the ice mold and the moisture in the box should be dried with a hair dryer, and placed in a place free of corrosive gas and ventilated and dry, to avoid open storage. Also need to pay attention to maintenance, pay attention to the strength, do not damage the explosion-proof high and low temperature machine.

Raccomandazioni correlate

-

How to reduce the failure rate of the new energy motor test water cooling system?

967New energy motor test water cooling system needs to pay attention to use during use, no matter how good equipment is used for a long time, some problems will occur more or less. So, how can we minimize the failure rate of the equipment during use?...

Visualizza i dettagli -

Introduction Of Low Temperature Refrigeration Equipment Series-low Temp Process Chillers

889Thermoacoustic refrigeration technology is a new refrigeration method with wide application prospects. It is one of the major advances in refrigeration and cryogenic technology in the past 30 years. Thermoacoustic engine uses thermoacoustic effect...

Visualizza i dettagli -

Guasti comuni e analisi delle cause dei refrigeratori raffreddati ad aria

1176During the use of air-cooled chiller equipment, it is inevitable to encounter some common faults. Users need to understand the possible causes of faults and make corresponding solutions in time, so as to make the production and operation more stab...

Visualizza i dettagli -

Temperature description of glycol chiller

998For users and friends, it is necessary tohave a deep understanding of glycol chillers before use. It is recommended toknow the temperature in various equipment such as refrigeration system,evaporating temperature, condensing temperature, etc.If...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore