Chip high and low temperature aging test box system design

The high and low temperature aging test box of the chip is applied to the high and low temperature test industry of the chip. The design schemes provided by the high and low temperature aging test box manufacturers of different chips are different, so how to design the high and low temperature aging test box design of the chip What?

The chip high and low temperature aging test box test system is divided into two parts: hardware and software. The software part includes the upper computer control program and the underlying control program. The host computer includes serial port communication, GPIB scan driver, and chip initialization parameter transfer setting (generation). Separate test units with pluggable stacks for different requirements (different speed requirements).

The production process determines the drift of its parameters, which is different according to different chips. The component of the test system uses the capacitance adjustment method to control the shedding voltage to achieve the starting voltage of the chip. The chip high and low temperature aging test box test system With the standard dialing of the measured chip, different dialing positions correspond to the combined test mode and the non-contact test mode. The trimming circuit section also has a manual adjustment section for easy online debugging.

In order to facilitate debugging during the production process, the upper computer mode adopts engineering mode and production mode. The engineering mode is mainly for the purpose of convenient debugging. The instructions that need to be used in the test process are implemented in a simple interface as much as possible, and the test statistics of each step. The chip high and low temperature aging test box test has serial test and parallel test. In order to speed up the test, the system adopts multi-module parallel test.

The chip high and low temperature aging test box system design and development of a chip-based finished product test system. The test system is based on the handshake communication principle of the read/write chip, applying multiple combinations, control of communication timing, and processing of data. Test chip defective products and qualified products have the same results, continuous testing, and good system stability. The system has passed the actual quantity product performance test, which has been applied in practice and is in good working condition.

Of course, the chip test system brought by different chip high and low temperature aging test box manufacturers is different. Therefore, the user can select the corresponding chip high and low temperature aging test box according to specific needs.

(Note: Some of the content is from related papers. If you infringe, please contact us in time to delete, thank you!)

Raccomandazioni correlate

-

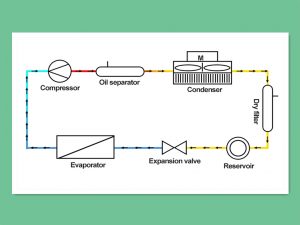

Troubleshoot the main points of failure of the high and low temperature cooling system

1209When the industrial high and low temperature cooling system is in use, what is the general reason if the temperature cannot drop down? How should we deal with such failures? Let's first analyze the principles and methods of industrial cooling. The...

Visualizza i dettagli -

Application and function of explosion-proof constant temperature circulation system

956Temperature control in drug research and development and chemical experiments, as well as temperature control in small-scale experimental production and industrial production, all require highly dynamic constant temperature controllers. The chemic...

Visualizza i dettagli -

Wuxi Guanya Analyses How to Judge Refrigeration Conditions of Refrigerated Water Chiller for You

853When purchasing refrigerated water chiller, if you want to know the quality of the chillers, you can see the refrigeration condition of the chillers. The refrigeration effect of the good chillers is relatively stable and efficient in long-term ope...

Visualizza i dettagli -

Istruzioni per la selezione del volume della camera per prove d'urto ad alta e bassa temperatura di piccole dimensioni

1235Quando il prodotto di prova (componenti, componenti, componenti o macchina completa) viene posto in una piccola camera di prova d'urto ad alta e bassa temperatura per il test, al fine di garantire che l'atmosfera intorno al prodotto di prova possa...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore