Performance Characteristics of 30 HP Water Cooled Chiller

The 30p water cooled chiller is an industrial water chiller with a horsepower of 30 HP. The water-cooled industrial water chiller must rely on the cooling water tower for work, while the air-cooled industrial water chiller uses its own fan for cooling, which has some requirements for the environment: for example, ventilation, humidity and temperature cannot be higher than 40 ℃, air pH value, etc.

Performance characteristics of 30p water-cooled industrial chiller:

1. The primary effect filter is set inside to ensure the heat exchange effect of the heat exchanger and prolong the service life of the heat exchanger.

2. Wide operating range, high temperature control accuracy and energy consumption saving.

3. Special microcomputer automatic control, easier operation.

4. Independent working circuit, energy saving and high efficiency.

5. Shell and tube evaporation heat exchanger is adopted, which has high efficiency, good stability, convenient maintenance and simple operation.

6. The protection function is complete, safe, reliable and durable.

7. Continuous capacity control can effectively improve the energy efficiency ratio of the unit and reduce the operation cost.

8. The product has complete specifications and wide selection range, which is suitable for all kinds of comfortable and process places.

9. Compact design, small volume, light weight, small floor area and small installation and maintenance space.

10. During operation, the load can be adjusted according to the load, and the efficiency of partial load operation is higher.

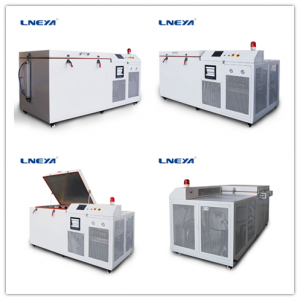

The industrial chillers independently developed and produced by our LNEYA not only have 30HP, but also have more choices. Different working conditions require different models. If you have questions or purchasing needs, please contact us at sales@lneya.com.

Raccomandazioni correlate

-

What are the requirements for the cooling and heating temperature control equipment of the 500-liter

907The 500-liter reaction kettle cooling and heating temperature control equipment is a dynamic temperature control system, a fully closed circulation pipeline, which can be automatically heated or cooled according to the process requirements. 1. A s...

Visualizza i dettagli -

Water cooled low-temperature circulators in the testing industry of new energy vehicles

980The development of the new energy vehicle industry is relatively rapid. Driven by technological innovation, it is believed that the new energy vehicle industry is facing opportunities. However, with the development of the new energy vehicle indu...

Visualizza i dettagli -

The main purpose of the ethylene glycol chiller for the heating and cooling unit of the reactor

1164The glycol chiller is suitable forhigh-purity metal, rare substance purification, laboratory environmentsimulation, magnetron sputtering, vacuum coating and other industries. Largecryogenic pump units can provide a cooling environment for labor...

Visualizza i dettagli -

How to solve the phenomenon of ultra-low temperature freezer card cylinder?

1408If the ultra-low temperature freezer room fails during operation, it needs to be solved in time. If it is similar to the related phenomenon, it may be that the frozen oil does not come up, and the operator needs to solve it in time. Ultra-low temp...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore