Cooling system of liquid-cooled energy storage cabinet-chiller

With the development of new energy technology, the application of containerized energy storage systems in new energy, photovoltaic, and electric energy stations has increased. If the temperature of the energy storage battery pack is not well controlled, the temperature of the battery will be unstable, leading to an increased risk of short circuit and damage to surrounding components.

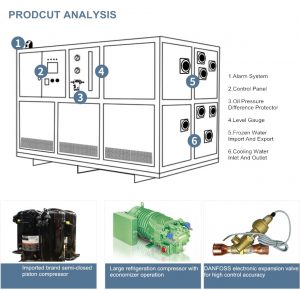

The containerized energy storage system is mainly composed of a containerized machine room, a battery management system, and a battery pack temperature control system. Therefore, the cooling system of the special containerized energy storage system is becoming more and more high-performance and highly stable. The temperature control system includes chillers, chiller pipes, air conditioners, and air ducts. Provide suitable and stable ambient temperature for the overall container energy storage system.

During the work of the containerized energy storage system, the lithium battery system, battery management system, energy storage monitoring and other systems will generate a lot of heat due to current changes. In order to ensure the efficient operation of the energy storage system at all times, some systems will be equipped with dedicated energy storage system cooling units , The cooling method is divided into two types: air-cooled and water-cooled.

LNEYA’s energy storage integrated cabinet cooling system follows a compact design and can be an external cooling system for the battery pack energy storage integrated cabinet. Efficient nanny-style thermal management system is suitable for applications where the battery inside the energy storage container generates a lot of heat and is sensitive to ambient temperature. Integrate upper computer communication, alarm and other functions, without complicated debugging.

Liquid cooling is integrated into each battery cabinet using glycol antifreeze. The system is fully enclosed design, supports dual system cooling circuits, mutual backup to avoid battery shutdown and safety failure; intelligent, multi-language color touch screen, provides clear and comprehensive important data information, and can display flow pressure data in real time; liquid cooling system IP50 The above protection can meet the anti-corrosion requirements, and can be used below 3000 meters above sea level. The temperature setting range is -45°C~55°C, and the liquid temperature can be precisely controlled within ±0.5°C.

Raccomandazioni correlate

-

Refrigeratore a raffreddamento liquido (accumulo di energia)

3174Model CNYL -45~55 Cooling Capacity 45KW Temperature Control Accuracy ±0.5℃ Real-time temperature record Secondary Refrigerant Ethylene glycol antifreeze, fully enclosed design of refrigerant circulation system Refrigerant R41...

Visualizza i dettagli -

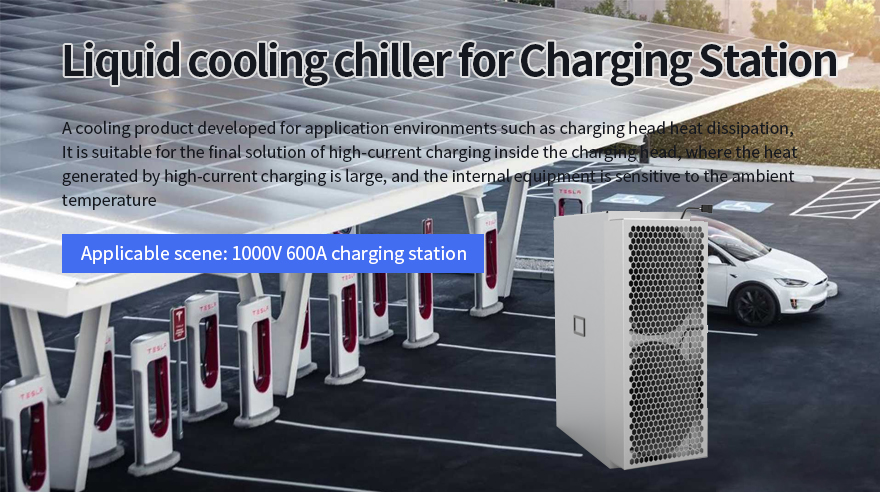

Refrigeratore di raffreddamento a liquido (pila di caricamento)

2246Model CHDYL-4 -45℃~55℃ Cooling Power 4KW Temp control accuracy ±1℃ Real-time temperature record Refrigerant Brine circulation system fully enclosed design Flow 1.8~5.5L/min Pressure 0.7bar Minimum water inlet temperature 15°C ...

Visualizza i dettagli -

Refrigeratore a raffreddamento liquido (accumulo di energia commerciale)

2319Battery Energy Storage Systems are filled with many battery cells, generating a large amount of extreme heat load. This means that the cooling system needs to precisely control the temperature and efficiently dissipate the l...

Visualizza i dettagli -

Come viene messo a terra il collaudatore di batterie per veicoli elettrici?

940Se il test della batteria del veicolo elettrico non è isolato tra la fonte di alimentazione CA e il bus CC dell'azionamento (ad esempio un trasformatore), non collegare la porta non isolata del bus CC o la terra del segnale non isolato alla terra, che potrebbe...

Visualizza i dettagli -

Cooperazione con i forti! Si è conclusa con successo la cerimonia di firma della cooperazione strategica LNEYA&Siemens

2568On May 25, 2021, the signing ceremony of strategic cooperation between LNEYA Constant Temperature Refrigeration Technology Co., Ltd. and Siemens (China) Co., Ltd. was held in Wuxi, China. At the signing ceremony, leaders such as Que Yaoyao, direc...

Visualizza i dettagli -

How to deal with organic waste gas treatment refrigerant leakage?

1137In the process of organic waste gas treatment, if it is found that the refrigerant leaks, it is recommended to treat it in time. LNEYA organic waste gas treatment professional manufacturer then analyzes the knowledge of organic waste gas treatment...

Visualizza i dettagli -

Industria e introduzione del refrigeratore a bassa temperatura

938Nella raffinazione del petrolio, nell'industria petrolchimica, nella sintesi organica, nei prodotti chimici e in altre produzioni industriali, la tecnologia della refrigerazione deve essere applicata per controllare la temperatura di reazione durante i processi di liquefazione, ...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore