Come risparmiare energia nell'unità di controllo del termostato di riscaldamento della camera a vuoto

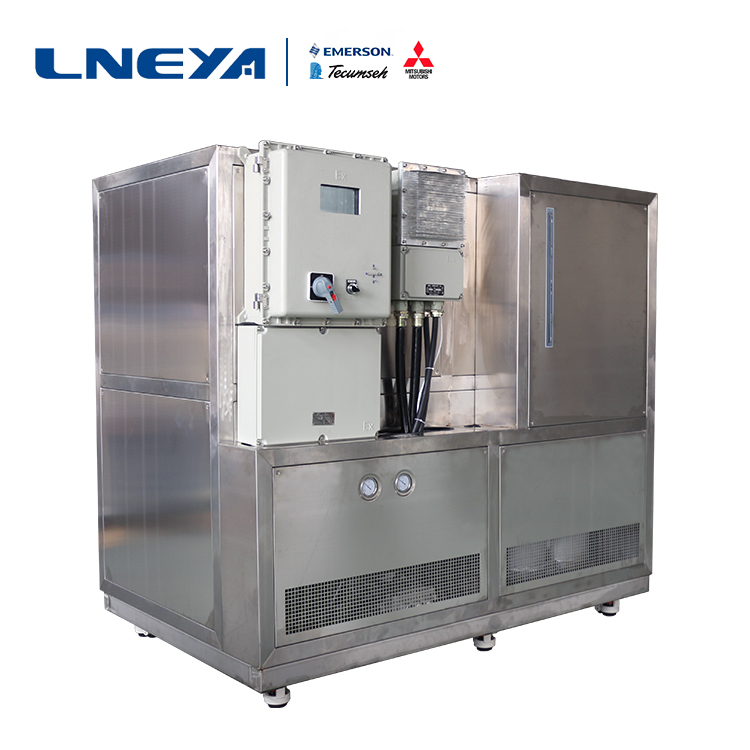

In the environment of energy-saving and emission-reduction operation, how to operate the LNEYA vacuum chamber cooling and heating thermostat control unit is very important. Let’s take a look at a few tips to reduce the consumption and see how to use it.

The very important first step in the selection of the vacuum chamber cooling and heating thermostat control unit is that the cooling capacity is too small, which affects the production, and often loses more than the loss; however, the excessive cooling capacity will inevitably increase the cost of the enterprise and cause unnecessary waste. It is recommended that the manufacturer introduce the detailed process in the process of purchasing, and let the professional personnel calculate the appropriate model, the object to be cooled and the time required to reduce the required temperature.

In this process, we must pay attention to some manufacturers to do some small articles on the cooling capacity, often exaggerating the energy efficiency ratio, in fact, these things can pay attention to the greasy ones, there are related data showing the cooling capacity power theoretically. Data, in the actual production process, the cooling capacity will be lower than the theoretical value, according to the actual situation of the environment, the cooling capacity will fluctuate.

The vacuum chamber refrigeration heating constant temperature control unit increases the evaporation temperature under the premise of ensuring the production demand and meeting the safety of the equipment or the product, and appropriately reduces the condensation temperature and increases the flow rate of the cooling tower to ensure the cooling water effect;

Improve regular daily maintenance work, regularly clean the pipeline, reduce pipe resistance and prevent pipe fouling, increase flow, ensure that the evaporator and condenser fully replenish water, enhance heat transfer efficiency, and unclean water source during long-term use. Will produce calcium carbonate and magnesium carbonate deposition pipelines, affecting heat transfer efficiency, increase the power required for the operation of the equipment, so that the electricity costs increase significantly, invisibly increase the cost of the enterprise.

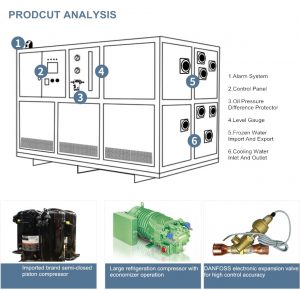

The LNEYA vacuum chamber refrigeration heating constant temperature control unit adopts a fully enclosed pipeline. In the process of operation, the energy consumption ratio can be reduced to a certain extent, so that the vacuum chamber refrigeration heating constant temperature control unit operates efficiently.

Raccomandazioni correlate

-

Test instructions for refrigeration heating temperature control system for fuel oil test

1156The refrigeration heating temperature control system can be tested for different projects during operation. The detection of different projects is different. Among them, the refrigeration heating temperature control system for fuel oil testing is ...

Visualizza i dettagli -

Industria e introduzione del refrigeratore a bassa temperatura

938Nella raffinazione del petrolio, nell'industria petrolchimica, nella sintesi organica, nei prodotti chimici e in altre produzioni industriali, la tecnologia della refrigerazione deve essere applicata per controllare la temperatura di reazione durante i processi di liquefazione, ...

Visualizza i dettagli -

When to choose TCU temperature control system?

975First of all, we need to know that the reaction kettle generally needs to carry out the necessary temperature control along with the chemical reaction of the material itself. Through the temperature change of the circulating medium in the jacket ...

Visualizza i dettagli -

Burning machine phenomenon in small high and low temperature integrated machine

861The small high-low temperature integrated machine is used for the temperature control of the connected reactor in the pharmaceutical, chemical and other industries. Once the burning phenomenon occurs during operation, we need to pay special attent...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore