What should do if the equipment of the thermal shock test chamber does not reach the set temperature

The choice of the manufacturer of the thermal shock test chamber is related to the quality of the thermal shock test chamber. Once the quality is set, the temperature setting of the equipment will not be closed. What should I do if I encounter the temperature setting problem?

The temperature set by the thermal shock test chamber is not up to the possibility that the heat exchange humidification tube is broken. You can either repair the factory or replace the new thermal shock test chamber directly. In the high temperature test, if the temperature does not change. When testing the temperature value, the electrical system can be inspected to eliminate the fault one by one, or the temperature probe may be broken, causing the device to not work when the water temperature is lower than the set standard temperature or 37 degrees.

The temperature and temperature of the thermal shock test chamber is too long or the heating tube is aging and damaged. When the actual water temperature is far below 37 degrees, the equipment has not worked, or the work is not working. If the temperature rises directly to cause over-temperature protection, the controller fails and the control instrument must be replaced. If the temperature is too high, you need to set the PID setting parameters first.

If the temperature rises very slowly, it is necessary to check the air circulation system to see if the regulating baffle of the air circulation is normally turned on. If the temperature of the thermal shock test box rises very quickly, check whether the motor of the air circulation is running normally. Because there is a time limit for use, so the running time is too long, it is inevitable that there will be some kinds of various faults, usually pay attention to regular maintenance and maintenance, generally can be largely avoided. If you encounter a large technical problem, you should seek solutions in time with the manufacturer.

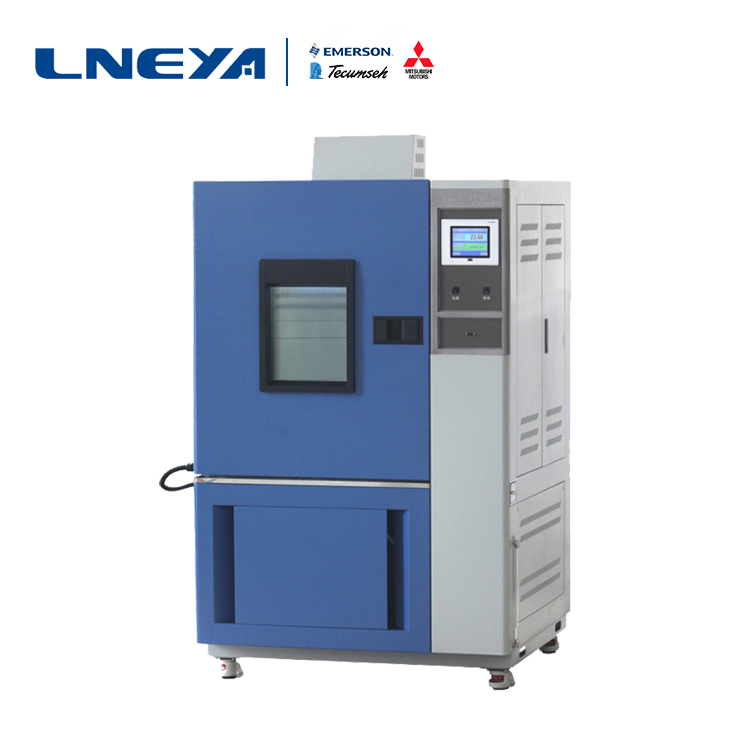

LNEYA thermal shock test box manufacturer is a professional hot and cold impact test box manufacturer integrating R&D, production and sales. It has more than ten years of experience in refrigeration and heating equipment production, and has reached cooperation with many domestic enterprises.

Raccomandazioni correlate

-

How to protect the zero-86 degree low temperature refrigerator?

1200The structure of the scroll compressor and the piston compressor in the low-to-86 degree low-temperature refrigerator is different, and it cannot be reversed. The reverse phase of the three-phase power supply of the low-zero-86 degree low-temperat...

Visualizza i dettagli -

60P ultra-low temperature water chiller consumes too much energy and needs attention

88060p ultra-low temperature water chillers of different manufacturers have different performance configurations and different energy consumption. If you find that the energy consumption is too large, you must check in time to see if there is a probl...

Visualizza i dettagli -

Come risolvere la mancanza di capacità di raffreddamento del sistema del ciclo di raffreddamento dei semiconduttori?

1051Il sistema a ciclo di raffreddamento dei semiconduttori è un dispositivo per il raffreddamento della parte riscaldante del semiconduttore nelle apparecchiature di refrigerazione. Viene comunemente utilizzato per testare parti di circuiti integrati a semiconduttore, parti elettroniche di autoveicoli, componenti di fibre ottiche,...

Visualizza i dettagli -

Points for Attention in the Use of Recirculating Chillers for Distillation Equipment

1099The recirculating chiller is a supportingdistillation equipment, which separates different mixtures by vaporizing andcondensing multiple times. It can be used well with the distillation equipment,which can not only improve its operating efficie...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore