High and low temperature device related instrument maintenance instructions

The liquid medium should be added before the high and low temperature circulation device is used. The liquid medium generally uses more than 95% alcohol, and the liquid medium cannot be lower than the working plate 20mm. The high and low temperature circulation pump should be placed in a dry and ventilated place with a distance of 400 mm from the obstacle on the back and sides. The working power supply of the high and low temperature circulating device should be determined according to the model of the machine (technical parameter column). The power of the power supply should be greater than or equal to the total power of the instrument. The power supply must have a good “grounding” device (Note: low temperature coolant circulating pump 380v voltage There is a grounding lead on the screw on the lower left side of the instrument). After the high and low temperature circulation device is used, all the switches must be turned off before the power plug can be unplugged. The high and low temperature device manufacturers use the suction ball and the skin tube to suck the liquid.

If the high and low temperature circulation device is operated below 0 °C, the door should be avoided as much as possible. Because when the temperature is low, if the door is opened, the internal evaporator and other parts will be sealed, especially the lower the temperature, the more serious the situation is. If you must open it, you should try to shorten the opening time. When the low temperature operation is completed, it is necessary to set the temperature condition at 60 ° C for drying for about half an hour, so as not to affect the measurement time or icing phenomenon of the next working condition. The high and low temperature circulation device radiator (condenser) should be regularly maintained and kept clean. After the low-temperature operation of the high-low temperature cycle device, if there is no work at the sixth point above, it is also necessary to set the normal temperature condition so that the temperature inside the box is normal temperature when the machine is stopped, so as not to affect the icing phenomenon caused by the low temperature inside the box. And the fogging of the window glass.

The use of high and low temperature circulation devices requires frequent maintenance, and proper maintenance can prolong the service life of the high and low temperature circulation devices and stabilize the operation.

Raccomandazioni correlate

-

What do the fault codes of air-cooled chillers mean

1173Generally, people will see 2 areas on thecontrol panel of the device, namely PV area and SV area. The first oneexpresses the specific temperature, and the latter one is for setting thetemperature. When a fault occurs, PV displays the number of ...

Visualizza i dettagli -

Temperature requirements for ion implantation chillers in semiconductor manufacturing processes

826Ion implantation is an important step in semiconductor manufacturing processes to precisely dope and control the electrical properties of semiconductor materials by implanting high-energy ions into them. This process generates a lot of hea...

Visualizza i dettagli -

The importance of temperature control equipment TCU in the pharmaceutical industry

9171.Low temperature conditions required for biochemical reactions inside the reactor: low-temperature drug synthesis, etc 2.Rapid cooling of raw materials to prevent drug spoilage, low-temperature crystallization and extraction. G...

Visualizza i dettagli -

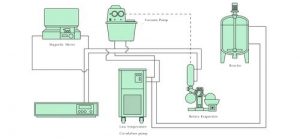

Low-temperature coolant circulation pump used with rotary evaporator

1255The chemical and pharmaceutical fields are the largest end consumer markets for cryogenic coolant circulation pumps. With the increasing demand for low-temperature coolant circulation pumps in this market, the application of cryogenic pumps in the...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore