How will the battery be affected when the fuel cell vehicle starts cold at low temperature?

At present, the topic of fuel cell vehicles in China is relatively hot. Fuel cell vehicles have the advantages of large market space, high technological status, short hydrogenation time, high battery life, and low pollution.

However, at present, fuel cell vehicles are in the embryonic stage of the industry, and there are still some obstacles in terms of infrastructure, cost, storage and transportation, and technology, which has caused the price of hydrogen fuel cell vehicles to remain high.

Today, look at why fuel cell vehicles are affected by cold start of hydrogen fuel cell vehicles.

No1: Low temperature cold start is one of the main factors affecting the commercialization of fuel cell vehicles

If the fuel cell operates at a continuously low or high temperature, there may be a safety risk. Especially in the colder areas of the north, the use will be limited.

Although with the advancement of technology, the current low-temperature and high-temperature working environment can already be solved by adding heating modules and heat dissipation systems, but the cold start of the fuel cell vehicle at low temperature still requires a relatively long time. Obviously, the low temperature cold start takes a long time is one of the technical problems facing fuel cell vehicles.

No2: Low temperature cold start is related to the structure of the fuel cell

The structure of a fuel cell vehicle is mainly composed of a driving motor, a power battery, a fuel cell system, and a vehicle controller. The main function of the fuel cell system is to convert hydrogen gas into electrical energy through an electrochemical reaction to charge the power battery and drive the motor. It is a very important part of fuel cell vehicles.

At present, most fuel cell vehicles on the market use proton exchange membrane fuel cells. Proton exchange membrane fuel cells (PEMFC) have various performance advantages, including low battery operating temperature (<100℃) and fast starting speed. At the same time, It is widely used in transportation and mobility, so the global shipments of proton exchange membrane fuel cells dominate.

However, the proton exchange membrane fuel cell (PEMFC) car also has a relatively big disadvantage when operating in a low temperature environment, that is, the cold start takes a long time.

No3: Low temperature reduces fuel cell performance, resulting in difficulty in cold start

Low temperature cold start means that the fuel cell vehicle can be successfully started at a temperature below 0°C, and can quickly raise the internal temperature of the fuel cell to 70~80°C to meet the performance of normal operation.

In the working environment without special protection and at 0 ℃, the water generated by the electrochemical reaction of the fuel cell is easily frozen to cause the catalyst layer and the diffusion layer to block, which hinders the progress of the electrochemical reaction, and the volume change caused by the freezing of water will also The internal structure of the fuel cell causes damage, resulting in a decrease in fuel cell performance.

Look at the fuel cell bus’s cold start experiment process at -30℃ low temperature environment. The vehicle is continuously frozen in the -30℃ environment for more than 20 hours. During the period, the vehicle is powered on to collect the temperature of the fuel cell and power battery, and record the temperature of the two. Decline the curve to evaluate the effect of the battery compartment warming measures; when the temperature of the fuel cell is ≤-20°C and the temperature of the power battery ≤-25°C, it is judged that the freezing stops.

The relevant conclusions of the experiment are as follows:

(1) The fuel cell can be successfully started in 15 minutes after freezing in a -30℃ environment for more than 20 hours;

(2) After the vehicle-mounted hydrogen system is frozen at -30℃ for more than 20 hours, there is no leakage at all pipeline connections.

In the field of hydrogen fuel cell vehicle research and development, Japanese car companies and Korean car companies are at the forefront, and mass production of hydrogen fuel cell vehicles has been achieved in passenger cars. Domestically produced hydrogen fuel cell vehicles are still based on passenger cars and special vehicles. the Lord.

Therefore, in the production process of hydrogen fuel cells, manufacturers must indispensable in order to ensure performance

To use the performance at different temperatures, after all, it is impossible for the battery to completely rely on its own heating and cooling cycle components to adjust the obstacles generated during use.

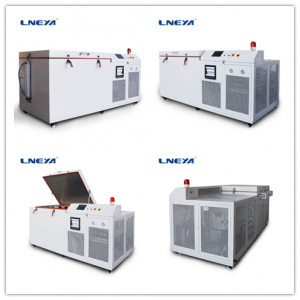

LNEYA KRY series electric vehicle battery motor test chiller for power battery charging management, used to test permanent magnet synchronous motor, switched reluctance motor, asynchronous motor and its precision temperature control device can be achieved through the LCD control panel + Remote control mode; with automatic fault protection function, it can output corresponding signals to ensure equipment safety. The main components are international brands, quality assurance, the surface is treated with high-voltage electrostatic spraying, and auxiliary equipment can be added according to specific needs. The test control temperature range is -40℃~+100℃, and the temperature control accuracy is ±0.5℃. The device can control the flow separately or individually, and it needs to control different solutions at the same time (customized).

Raccomandazioni correlate

-

Effect of cooling and heating temperature cycle during emulsification

1550Emulsification is the effect of a liquid in which even tiny droplets are evenly dispersed in another liquid that is incompatible with each other. Emulsification is a liquid-liquid interface phenomenon. Two immiscible liquids, such as oil and water...

Visualizza i dettagli -

Description of pump selection in steam-saturated system temperature control unit

1041The steaming system temperature control unit is one of the more used equipment in the pharmaceutical chemical industry. The performance of the LNEYA steaming system temperature control unit depends on the design of the whole system and the specifi...

Visualizza i dettagli -

Description of LNEYA industrial ultra-low temperature freezer

1234LNEYA industrial ultra-low temperature freezer is mainly used in industrial cold treatment to precipitate uniform, fine and dispersed carbides on the metal structure matrix. The appearance of such a carbide will bring about a significant increase ...

Visualizza i dettagli -

Quali sono i refrigeranti comunemente utilizzati per la selezione dei marchi di refrigeratori?

1084When the enterprise chooses the refrigerant in the cryo chillers unit brand, what should it need to pay attention to the present market commonly used refrigerant? What is the difference between specific refrigerant properties? Take a look at the b...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore