Solution to High and Low Pressure Fault of Water Cooled Chiller

The method to eliminate the shortcomings of high and low pressure of water-cooled chiller has always been a key point and difficulty in the industry, so it is very important to master the solutions to the shortcomings of high and low pressure of water-cooled chiller. The reason can be preliminarily identified as poor water quality, and corresponding impurities (leaves, weeds, etc.) enter the water distribution hole, which affects the heat dissipation of the cooling water tower. Next, I will introduce the reasons and solutions for the high and low pressure disadvantages of a water-cooled chiller.

Causes and solutions of high and low pressure disadvantages of water-cooled chiller:

In the application of water-cooled chiller, we often encounter high and low pressure alarm of chiller! In terms of high pressure, it is generally poor heat dissipation, which will lead to poor cooling effect of the chiller. For a long time, high pressure will also lead to high current and burn out the compressor. Generally, there is no cold coal or cold coal leakage in the low pressure alarm. The compressor will also be damaged if it works at low pressure for a long time.

Generally, water-cooled chillers have high and low pressure gauges, which are divided into high pressure and low pressure. In addition, industrial chillers are roughly divided into air-cooled chillers and water-cooled chillers: at present, the surface plate of industrial chillers on the market is divided into computer board and manual control board. High pressure and low pressure of computer board are well separated, but generally, the high and low pressure alarm lights of manual control board chillers are together, so it is not so easy to distinguish.

Therefore, you should first know whether the chiller you are using is an air-cooled chiller or a water-cooled chiller, whether it is a computer board or a manual control board, whether it is a high-pressure alarm or a low-pressure alarm. For the high-pressure alarm of the air-cooled chiller, you need to clean the cooling network, and for the low-pressure alarm, you need to check whether the cold coal leaks or the pressure gauge has no pressure, The high pressure alarm of water-cooled chiller requires cleaning the condenser. Low pressure alarm also depends on whether the pressure gauge has no pressure, so it is necessary to check the leakage, make up the deficiency and add cold coal.

Raccomandazioni correlate

-

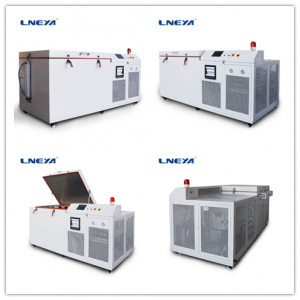

Description of LNEYA industrial ultra-low temperature freezer

1236LNEYA industrial ultra-low temperature freezer is mainly used in industrial cold treatment to precipitate uniform, fine and dispersed carbides on the metal structure matrix. The appearance of such a carbide will bring about a significant increase ...

Visualizza i dettagli -

Maintenance of Top 10 Industrial Freezers

1175When we choose and buy industrial freezers of top 10 brands, in addition to some necessary needs, we should also pay attention to the use and maintenance of the industrial freezer, we should select industrial freezers with long service life, high ...

Visualizza i dettagli -

Istruzioni per la manutenzione dell'incubatore di semiconduttori ad alta precisione

1241L'incubatore di semiconduttori ad alta precisione è nello stato dell'evaporatore come refrigerante gassoso; dopo il restringimento adiabatico della macchina di restringimento, diventa uno stato ad alta temperatura e ad alta pressione, e il refrigerante gassoso contratto è...

Visualizza i dettagli -

Won the “2021 High Quality Development Award”

1597On the afternoon of May 8, 2022, the 2020 Annual Summary and Commendation Conference was held in Hongshan Street, Wuxi City. Wuxi Guanya Constant Temperature Refrigeration Technology Co., Ltd. (LNEYA) won the "2020 Outstanding Contribution Award"...

Visualizza i dettagli

Refrigeratori industriali LNEYA Produttore Fornitore

Refrigeratori industriali LNEYA Produttore Fornitore