LD -80℃~-30℃

Water Cooled Chiller- Cooling capacity @-75℃4kW~180kW

- Power range14kW~588kW

- Expansion tank100L~750L

- RefrigerantR404A/R23 or R508B

- Weight950KG~8000KG

- Place of OriginChina

Product data download

Configuration Details

| Model | LD-4W | LD-6W | LD-8W | LD-12W | LD-20W | LD-30W | LD-40W | LD-60W | LD-90W | LD-120W | LD-180W |

| Temperature Range | -80°C~ -30°C | ||||||||||

| Cooling Capacity At -75°C |

4kw | 6kw | 8kw | 12kw | 20kw | 30kw | 40kw | 60kw | 90kw | 120kw | 180kw |

| 3440Kcal/h | 5160Kcal/h | 6880Kcal/h | 10320Kcal/h | 17200Kcal/h | 25800Kcal/h | 34400Kcal/h | 51600Kcal/h | 77400Kcal/h | 103200Kcal/h | 154800kcal/h | |

| Circulation Pump Info | 6.6m³/h | 6.6m³/h | 9m³/h | 15m³/h | 25m³/h | 25m³/h | 25m³/h | / | / | / | / |

| 2.5bar max | 2.5bar max | 2.5bar max | 2.5bar max | 2.5bar max | 2.5bar max | 2.5bar max | / | / | / | / | |

| Inlet&outlet connection size | DN-25 PN-10 |

DN-25 PN-10 |

DN-32 PN-10 |

DN-40 PN-10 |

DN-50 PN-10 |

DN-50 PN-10 |

DN-50 PN-10 |

DN-65 PN-10 |

DN-65 PN-10 |

DN-80 PN-10 |

DN-80 PN-10 |

| Cooling Water at 30 degree | 10m³/h | 14m³/h | 20m³/h | 25m³/h | 35m³/h | 45m³/h | 65m³/h | 90m³/h | 120m³/h | 180m³/h | 250m³/h |

| Expansion tank(standard) | 100L | 175L | 250L | 350L | 500L | 600L | 750L | / | / | / | / |

| Compressor | Dorin semi-closed compressor | Dorin compressor/HANBELL、Fusheng、Bitzer screw compressor | |||||||||

| Operation Panel | 7-inch color touch screen display, temperature curve record | ||||||||||

| Control System | PLC&Module,Set temperature difference of refrigeration on & off | ||||||||||

| Circulation Pump | The whole system is a full closed circulation, there is no oil mist at high temperature and no water vapor at low temperature, pressure do not rise up when system is running. The system will supplement oil automatically at low temperature | ||||||||||

| Circulation Pump | LNEYA Mangetic Pump | ||||||||||

| Evaporator | Plate heat exchanger | ||||||||||

| Condenser | Casing type water-cooled condenser / tube-type water-cooled condenser | ||||||||||

| Intermediate heat exchanger | Plate heat exchanger | ||||||||||

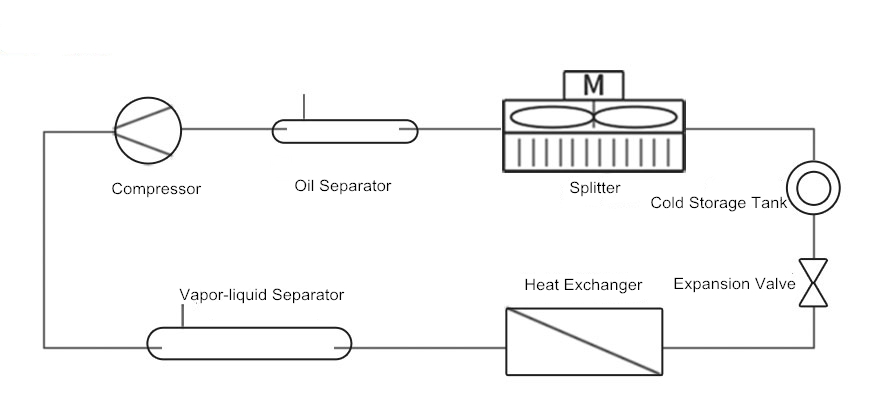

| Refrigeration accessory | Oil separators, drying filters, expansion valves, refrigeration solenoid valves, pressure control, mirrors, etc. all use Emerson / Danfoss and other brands | ||||||||||

| Electric | AC contactors, intermediate relays, circuit breakers, thermal relays, etc. are Schneider / ABB brand | ||||||||||

| Refrigerant | R404A/R23/R508B | ||||||||||

| Secondary refrigerant | Ethanol, dichloromethane, heat transfer oil, etc. | ||||||||||

| Safety Protection | High pressure protect; water supply cut-off protection; over-current protection; leakage protection; sequential and phase failure protection; High temperature protection; Sensor Failure protection; Liquid low level protection etc. multi-safety protection | ||||||||||

| Level Indicator | Adopt glass liquid level indication | ||||||||||

| Piping material | Expansion tank, cold storage tank and circulation pipeline are all made of SUS304 | ||||||||||

| Case material | Channel steel + square tube + cold rolled plate sealing plate spray 7035 | ||||||||||

| Dimension cm | 100*150*185 | 200*145*205 | 200*145*205 | 250*145*225 | 250*145*205 | 350*160*245 | 400*160*245 | 400*160*245 | 500*200*260 | 650*200*260 | 650*220*260 |

| Power | 24kW | 27kW | 38kW | 51kW | 69kW | 101kW | 136kW | 200kW | 295kW | 396kW | 588kW |

| dB | within 75 dB | within 80 dB | within 90 dB | ||||||||

| Weight (kg) | 950kg | 1100kg | 1400kg | 1800kg | 2200kg | 3000kg | 3500kg | 4000kg | 5000kg | 6000kg | 8000kg |

| Optional | Optional outside touch screen display controller (separated), the communication line distance is 10 meter | ||||||||||

| Optional | Optional explosion-proof touch screen control system (ExdeIIBT4), the communication line distance is 15 meter | ||||||||||

Product Description

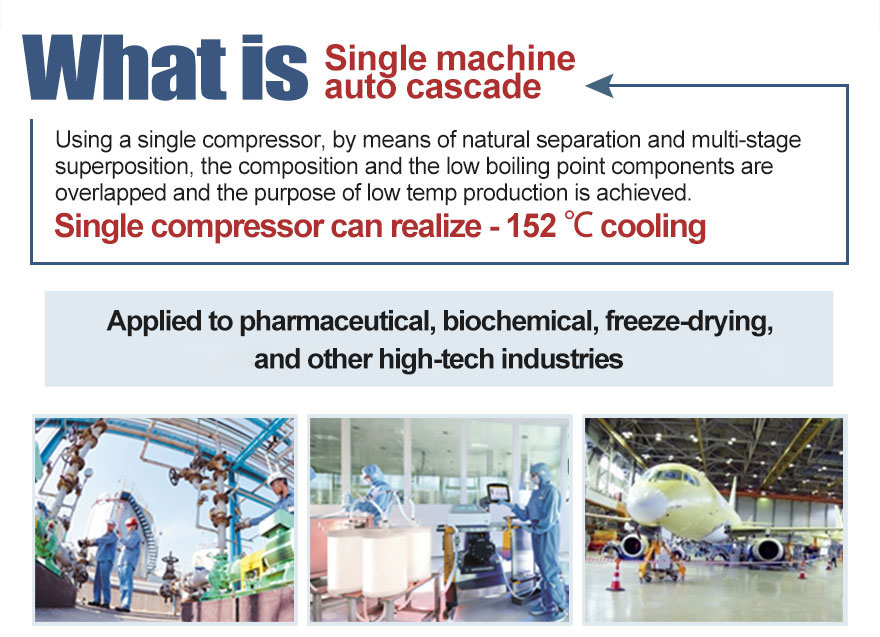

1.Temperature ranges from -5℃ ~ -150℃, can meet different temperature

2. Famous brand semi-closed piston compressor, semi-closed bipolar piston compressor, semi-hermetic screw compressor, main brand are BOCK. Bitzer, Copeland, Handbell, fusheng; Plate heat exchanger, Small volume, High efficiency

3. Top imported cold controller; Generator cooling water circuit uses intermediate heat exchanger, improve system reliability and safety.

4. DANFOSS electronic expansion valve, high precision control;

5. Adopt Siemens PLC S7-200/300, LNEYA touch screen, automatic control, temperature curve display, temperature record U disk, fault alarm;

6. Offer machine installation and system test, users only need to finish the installation of refrigerant and cooling water.

Chiller Knowledge

Maintenance for Lubrication System of Water Cooled Chiller Plant

When the chiller is below 80 ℃ ~ 30 ℃ below zero in the running system, people pay more attention to refrigerator, frozen water cycle system and electric control system, so the lubrication system is often overlooked. However, this system is also very important to the chiller. The maintenance of the chiller is indispensable, now we are going to tell you something about it.

1. Observe the normal oil surface, oil temperature and oil pressure in the daily inspection.

2. Regularly check the oil quality according to the oil change index stipulated in the frozen lubricating oil, and replace or supplement the filtered new oil.

3. Pay attention to check and adjust the end face clearance of the oil pump in the middle and overhaul, and replace the pump when necessary. The end face clearance of the pump varies from 0.03 to 0.08mm. Please refer to the assembly technical requirements and factory regulations of the pump for concrete value.

4. Regularly replace or clean the filter core, pipeline, and crankcase.

The maintenance of the lubrication system of the chiller requires techniques, which mainly involves the performance of the compressor’s main engine. It is recommended to be operated by professionals to avoid unnecessary losses.

recommend products

LJ -45°C~ -10°C

Cooling capacity @-20℃ 12kW~360kW Power range 12kW~270kW

LN -60°C~ -10°C

Cooling capacity @-55℃ 6kW~180kW Power range 14kW~300kW

SLJ -110℃~-150℃

Cooling capacity 2.5kW~11kW Power range 12kW~36kW

CDLJ -110°C~ -50°C

Cooling capacity @-105℃ 2kW~120kW Power range 14kW~768kW

loading…

已经是到最后一篇内容了!

Industrial Chillers Manufacturer Supplier - LNEYA

Industrial Chillers Manufacturer Supplier - LNEYA